| Columns Retired Columns & Blogs |

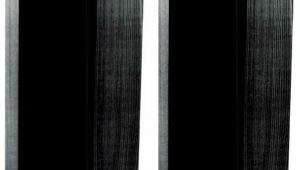

Snell Type C/IV loudspeaker Page 2

The C/IV's crossover was designed with a computer program after all the drivers had been measured in the enclosure in which they were intended to work. Crossover development programs are much more accurate at predicting real-world behavior when given the precise driver responses measured in a cabinet. The fourth-order slopes are achieved by a combination of crossover rolloff and the drivers' acoustic rolloffs. The woofer circuit uses non-polarized electrolytic capacitors and air-core inductors, while the midrange circuit uses electrolytics bypassed with Mylar caps. Tweeter filtering is provided by Mylar capacitors.

Footnote 1: See Tom Norton's interview with Kevin Voecks in Vol.13 No.3.

Because raw driver responses vary greatly from one unit to the next, a particular pair of loudspeakers may sound quite different from the next pair off the assembly line and in relation to the prototype. Snell overcomes this problem by measuring each driver and tweaking crossover components to compensate for driver variations. Capacitor, inductor, and resistor values are adjusted for the particular drivers in each pair of loudspeakers. The goal is to make each loudspeaker identical in performance to the prototype—within real-world limitations. Snell guarantees that each loudspeaker will have a frequency response within 0.5dB of the design goal. In practice, Snell loudspeakers typically achieve 0.25dB matching.

Although some speaker manufacturers match drive-units between stereo pairs—essential for good imaging—Snell's exacting procedure is, to my knowledge, unique. This procedure is performed on all Snell loudspeakers, including the $465/pair Type K/II. Besides ensuring that all loudspeakers will sound the same, this method allows exact matching of replacement drivers in case of failure. When Snell sends a replacement driver, relevant crossover components are also sent so that the repaired loudspeaker still matches the prototype (and its companion) to within 0.5dB.

The enclosure is made from ¾" high-density particle board, except the front baffle, which is 1½"-thick particle board. Two horizontal braces add rigidity to the cabinet. The midrange is mounted in a cylindrical sub-enclosure, rather than in a sealed cabinet section as was used in the Type C/III. This change between the III and IV version added volume to the woofer enclosure, smoothing bass response and extending the low-frequency cutoff point. Although some Kevin Voecks designs use a sealed enclosure (the Type K/II, for example), the majority of them—including the Type C/IV—are ported. A 3" port toward the lower rear of the enclosure vents low-frequency energy outside the loudspeaker.

The Type C/IV's fit and finish is excellent. Cabinet pairs are made from veneers taken at different depths from the same wood, ensuring matching grain. Once the veneer is cut, the cabinets stay in pairs throughout the manufacturing procedure.

Snell's design philosophy is based on using cost-effective components that can be shown to make an audible difference rather than spending money on esoteric parts that Snell feels may make a marginal improvement (footnote 1). This approach is contrasted with Hales Audio's ideology of using the best components money can buy, paying careful attention to the smallest details, and letting the product's retail price reflect this less cost-conscious approach. (The Hales System Two is reviewed elsewhere in this issue.) An example of these disparate schools of thought is found in the Type C/IV's and System Two's internal wirings. The Type C/IV uses regular 16-gauge wire to connect the drivers, the same wire you'd buy off a reel in an electronics store. The System Two is wired with Cardas cable, with the lengths from crossover to drivers identically matched. In addition, the Type C/IV uses electrolytic crossover caps, the System Two expensive Solen caps. These are just a few examples of the two companies' divergent approaches to building loudspeakers. These differences, however, are reflected in the prices: $2190 for the Type C/IV, $3000 for the System Two.

Listening

I used the Type C/IV as my primary loudspeaker for three weeks before conducting direct comparisons with the Hales System Two, which I'd listened to during the previous month.

I positioned the Type C/IVs in accordance with Snell's computer-generated recommendation for my room. Snell has developed a program that suggests rear- and side-wall distances (best, better, good) to minimize resonant-mode excitation. I have used their recommendations, with successful results, for some time with other loudspeakers. The C/IVs were positioned 50" from the rear wall (middle of woofer to wall) and 34" from the side walls. I toed-in the C/IVs a little more than halfway between pointing straight ahead and pointing directly at the listener. My listening chair positions my ears at 36", 3½" below the tweeter axis. All auditioning was done with the grilles in place.

I began with the rear-firing tweeter turned off. When I threw the switches that turn them on, one of the tweeters didn't work. It turned out that a bad solder joint on the rear tweeter was to blame: a few minutes with a screwdriver and soldering iron cured the problem. After some experimentation, I decided to leave the rear tweeters on. They didn't seem to change the overall tonal balance, but did add a sense of spaciousness and air to the presentation.

Footnote 1: See Tom Norton's interview with Kevin Voecks in Vol.13 No.3.

- Log in or register to post comments