| Columns Retired Columns & Blogs |

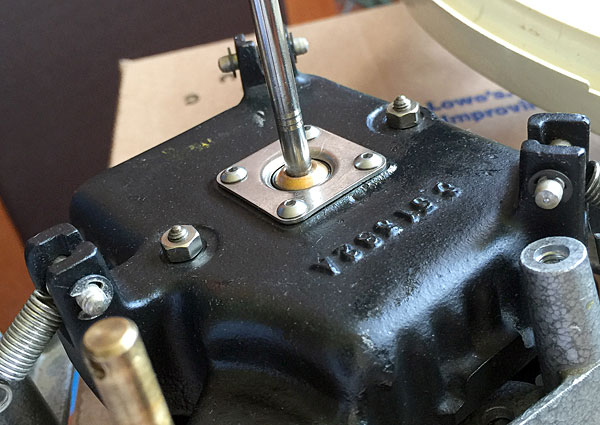

That goes for anything on the 301 with rubber/felt bushings, including bolting down the chassis to the plinth. I also always give the platter a gentle assist to get it going, and keep stress off the spindle, if I know the grease is cold.

I also see you made some dimensional changes to your plinth, as well as the mount. What's the skinny with that arm board you're using?

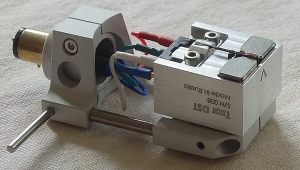

As for the new SPUs, I'm certainly still totally in love with my Zu/DL-103 MK.II, but I think I need to re-evaluate my Christmas list. Thanks for the breakdown on the differences between the E and S models.