| Columns Retired Columns & Blogs |

Listening #75

During a century of development of the phonograph, dozens of different things have been considered crucial to its performance: lack of bearing noise, lack of motor noise, freedom from runout error in the platter, high moment of inertia in same, immunity to all manner of unwanted vibration, and so forth. But now I wonder if the most important factor of all hasn't been overlooked, or at least misunderestimated, throughout much of that time: Could it be that motor torque is more critical than any of us imagined?

Footnote 1: By that I don't mean to imply that the small, low-torque motors used in many contemporary belt-drive turntables are too cheap. In the recent past I've had the opportunity to research the two 50Hz, 250rpm motors that are most popular among flat-earth manufacturers in particular; both were developed specifically for use in record players, and both are very well made, as far as that goes.

Empirical evidence has been piling up in my little corner for a year or two: The turntables that have impressed me most during that time—the ones that are the most musically compelling, and that tease from my records the greatest degree of musical flow, momentum, drama, and sheer force—all have high-torque motors.

Evidence of a labbier sort is lacking. Every so often, an engineer purports to "prove" that the resistance produced by a playback stylus in contact with a modulated groove is not enough to affect the speed at which the latter is pulled along under the former. I'm unconvinced, partly because none of these engineers has appeared to consider all of the interrelated variables at play—including the fact that stylus pressure is subject to constant change in response to rising and falling record surface imperfections—and partly because none has offered a reasonable means of measuring the phenomenon under actual playback conditions.

The dilemma, if that's what it is, reminds me of the one surrounding the acceptance of various digital-audio distortions as real. You may remember when the mass-market industry and their lackeys in the press told us that the Compact Disc was perfect—but:

"It doesn't sound perfect. In fact, it isn't nearly as listenable as analog."

"Nonsense. The math proves that the system is without flaw."

"Wait a minute: It turns out there's jitter in the output. That's certainly a flaw."

"Well, okay, there are flaws, but the math proves that they're inaudible . . . "

Sigh.

Hey, the rusty lug nut

Let's assume for just a moment that motor torque really does affect the quality of phono playback, in a more-is-better sort of way. How can we get more of it? And what could possibly be gained by disregarding it?

Let's have a look: In a typical alternating-current electric motor, and setting aside any number of pesky if not inconvenient variables, torque is a function of magnetic flux and armature current, which themselves are roughly proportional to the overall size of the thing. In English: Big motors are often torquier (rhymes with porkier) than little ones.

The relationship between motor torque and motor noise is less straightforward, but two interesting factors come into play. First, electric motors tend to exhibit maximum torque at lower speeds and maximum noise at higher speeds. Hmm. Second, with respect to armature shafts and bearings, it's easier to make a large motor that's free from wobble and runout error (and thus mechanical noise) than a small one. Hmmmm. So again: Why would someone design a turntable around a small motor instead of a big one?

Two reasons come to mind: First, in a product such as a manual turntable, the operation of which most users will attempt to pause but not stop every 20 minutes or so in order to change the record, low torque is quite simply easier to deal with. Fair enough. Second, and probably more germane, small, low-torque motors are a good deal less expensive to make than big, high-torque ones (footnote 1).

There's more to it than that, of course. In the 1960s, phonograph makers in search of new lands to conquer turned their attention to suspended-subchassis designs, wherein the motor drove a small-diameter subplatter by means of an elastic belt (footnote 2). To make such a thing was itself to diminish the importance of torque: According to the laws of physics, applying the driving force nearer to the center of the platter than to its periphery slashes torque to a minimum. Yet if the quest for torque had ever been deemed important, it was overruled then and there by belt drive's secondary appeal as a simple, cheap way to drive a platter, now that the range of compulsory disc speeds had been reduced by the extinction of 16rpm and the marginalization of 78rpm.

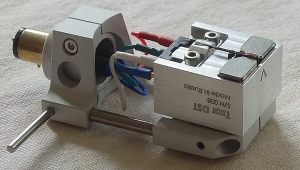

Coincident with the advent of suspended-subchassis turntables came a new wave of phono cartridges and the tonearms to accommodate them. Stylus profiles became smaller and more exotic. Cantilever compliance went up virtually across the board, and, most significant of all, tracking force went way down. All of that was hailed as a boon for our LPs—which was meaningless, inasmuch as record quality would sink to unimagined lows within another decade. If motor torque ever had been needed to overcome stylus drag, everyone reckoned, it wouldn't be needed any longer.

Prior to all that, idler drive was the norm, with a rubber-edged wheel between the motor pulley and the rim of the platter: By applying the motor's force to a point as far as possible from the platter's center, torque was maximized. (The same principle is at work when, to loosen a rusty lug nut, you use a breaker bar to extend a wrench's effective length.) Idler drive and powerful motors were the order of the day for radio DJs, who needed record platters that could attain full speed virtually instantly, but they were good for domestic users, too: The classic turntables of the 1950s could pull groove modulations under those classic, low-compliance pickups like nothing else—with steady, inexorable, unrelenting power.

You can hear that quality the same way you can hear anything else important: Stop listening to the sound and concentrate on the music. I daresay you'll hear a more human sense of touch in recorded music when it's played back on a high-torque player with a low-compliance moving-coil cartridge. It isn't just that drums are hit harder and basses are plucked more forcefully—although that's certainly true—but that virtually every kind of recorded music becomes more nuanced. I heard it just today when I played Philip Glass's Glassworks (CBS 37265) on my most recently restored Thorens TD-124, with my EMT 997 tonearm and a Shindo-modified Ortofon SPU pickup head. Music that might sound like a monotonous background wash on some players was transformed into an unignorable performance, simply by calling my attention to the way that different notes, in different portions of each measure, are emphasized by the musicians each time through. Very cool.

A Voyd in all but name

Back in 1985, a young engineering-school graduate named Guy Adams faced a similar dilemma: He admired the Linn LP12 and other such turntables for the strides they represented in LP playback, but nonetheless felt that something was missing. Adams set about designing and building his own turntable, but wasn't willing to give up the performance gains granted by a suspended subchassis. Neither did he wish to turn his back on the absence of unwanted energy storage offered by the then-current polymer platters, or the relative simplicity of belt (vs idler) drive.

The challenges were many, but the solution proved simple—and effective: Adams built a thoroughly modern belt-drive turntable in which a beautifully machined acrylic platter was driven by three powerful aussenlaufer (outer runner) motors. Significantly, all that torque wasn't squandered on a puny subplatter, but was applied directly to an inner rim machined into the underside of the platter itself, a full 11cm from the spindle. Also significant: Guy Adams made his turntable look good, with a wooden plinth so simply yet distinctively beautiful that you couldn't imagine why such a thing had never been made before.

Footnote 1: By that I don't mean to imply that the small, low-torque motors used in many contemporary belt-drive turntables are too cheap. In the recent past I've had the opportunity to research the two 50Hz, 250rpm motors that are most popular among flat-earth manufacturers in particular; both were developed specifically for use in record players, and both are very well made, as far as that goes.

Footnote 2: Of course, I'm setting aside the even less convenient subject of direct-drive turntables, partly because I haven't the time or space to go into them, and partly out of politeness: Putting the record in direct contact with the phonograph's No.1 source of unwanted vibration, whether of high or low frequency, has never impressed me as a terribly bright thing to do.

- Log in or register to post comments