| Columns Retired Columns & Blogs |

You're a moron, Fremer, and always have been. LPs suck and always have.

Over dinner that evening he regaled Pear Audio's North American importer, Michael Vamos of Audio Skies, and me with turntable stories dating back to the late 1970s and the Linn Sondek LP12, which, until the early '80s, he distributed in Czechoslovakia. In the mid-'80s, Mezek was involved in the development and distribution of the Rational Audio turntable, designed for Mezek by Jirí Janda (pronounced Yeerzhee Yahnda), who died in 2000. For those of you old enough to remember, Janda, a founder of NAD, designed that company's 5120 turntable; among other features, it had a flat, flexible, plug-in tonearm that you could easily swap out, much as you can with VPI's current models.

The Czech-built Rational Audio turntable featured a tangential-tracking tonearm built into the cover of a clamshell-like plastic chassis. The arm rode on wheels that ran on a metal rod—sort of like a simplified Souther arm, which morphed into Clearaudio's tangential tracker.

Mezek told me about the time his store was visited by Linn Product's founder, Ivor Tiefenbrun. From another room, someone played the Rational turntable. When Tiefenbrun was then led into that room and heard the sound, he just about had a cow. Mezek said that Tiefenbrun took a Rational back with him to Scotland, plopped it down on an engineer's desk, and asked, basically, why Linn couldn't do a turntable like this.

The NAD 5120 was actually a rebadged Tesla NC470, manufactured by Tesla Livotel, a Czech factory that produced everything from refrigerators to vacuum cleaners. The division of Tesla Livotel that made turntables eventually became Heinz Lichtenegger's Pro-Ject factory. Mezek knew Lichtenegger from their days in Vienna, way back when. Mezek told me why he was in Vienna, but I forget. A tequila-and-hair-tonic margarita mix can do that. More recently from the Pro-Ject factory comes the E-Flat turntable, also with a flat (but not flexible) tonearm, built for the European Audio Team (EAT), whose CEO, Jozefína Krahulcov†, is Lichtenegger's wife.

Mezek had a close relationship with the late Tom Fletcher, founder of Nottingham Audio and designer of the turntables that company produced during his lifetime. Mezek was also a longtime distributor of the Well Tempered turntable, but when the brand changed hands and Mezek found the supply of parts and manufacturer support waning, he dropped the line. Fletcher then stepped in to fill the distribution void by designing for Mezek a new turntable. The first Pear Audio Blue turntables were manufactured at Nottingham Audio's factory.

Fletcher and Mezek worked together for many years. Fletcher shared his design secrets and technology with Mezek, who shared his wide experience of handling and distributing thousands of turntables from multiple manufacturers, as well as tweaks for maximizing their performance. Before Fletcher died, he passed on to Mezek all of his design secrets. Mezek has kept alive Fletcher's ideas throughout Pear Audio's Blue turntable line, and has added some of his own. At RMAF, Pear Audio Analogue introduced their lowest-priced turntable, the Robin Hood. Every Pear Analogue Blue turntable is hand-built in Slovenia by Peter Mezek, and is subjected to extensive quality control before leaving the shop.

Pear Audio Blue Kid Thomas turntable

The Kid Thomas costs $5995. Add $1995 for an outboard power supply built by Martin Bastin that comprises a 60Hz AC sinewave regenerator and fine speed adjustment controlled with a knob on the supply's front panel.

Unpacking the Kid Thomas makes obvious the turntable's artisanal quality: lots of hand-cut foam and plastic wrap that tightly secure the double plinth, made of an attractive but unspecified wood. Elegant the packing is not! Three adjustable feet attached to the bottom of the lower plinth end in buttons of moderately soft polymer, and polymer or Sorbothane discs between the plinths provide damping and isolation. The lower plinth supports the substantial bearing assembly, which appears to be a standard bushing of brass or bronze.

The arm-mounting platform, made of acetal polyoxymethylene copolymer (POM), attaches to the upper plinth. Attached to the lower plinth and extending upward out of a circular well machined into the upper plinth is a small-diameter spiral tube made from a gray material stiff enough to support itself while remaining somewhat soft and compliant. After pouring a specified amount of a special oil into the bearing well, you lower into the bushing the spindle bearing, which is attached to the tall, full-sized 25-lb platter of aluminum alloy. The spiraled tube contacts the bottom of the platter to apply a minute amount of braking to the platter's rotation. But even with this friction applied, the platter will still rotate for a very long time. Mezek told me that the hardness of the spindle bearing varies from the top to the bottom of the shaft.

As in the Nottingham turntables, damping rings of thick, elastic rubber fit into grooves machined into the platter's rim. I tapped on the platter with a screwdriver before and after installing the rings and easily heard their effectiveness—at least in damping impulses that would otherwise cause the platter to ring.

Driving the exceptionally heavy platter is an exceptionally puny, low-torque, 117V AC motor housed in a round POM cylinder press-fitted into a larger POM disc that sits on elastomer feet. To adjust the motor's height, you press down or push up on the cylinder. Place the motor housing beside the cutout on the left-hand side of the plinth and fit the stretchy silicone drive belt around the 331/3 or 45rpm pulley and the platter. Place atop the platter the thin foam record mat, and setup is almost complete.

If you read my review of Palmer Audio's 2.5 turntable in the November 2014 issue, and/or are familiar with the Nottinghams, this should sound familiar: they and the Kid Thomas all have heavy platters, low-torque motors, and Martin Bastin power supplies.

When I mentioned the Palmer 2.5 to Mezek, he involuntarily made a face, probably out of loyalty to Tom Fletcher, from whose design strategy the Palmer appears to borrow. He insisted that while both companies use Bastin power supplies, the supplies are not the same. Mezek said that he's using Fletcher's approved version in the Kid Thomas, and that, compared to the newer, updated power supply, there's no sonic comparison. If I wanted to hear for myself, he had both up in his hotel room. Power-supply comparisons at 10pm on the last day of an audio show? I declined.

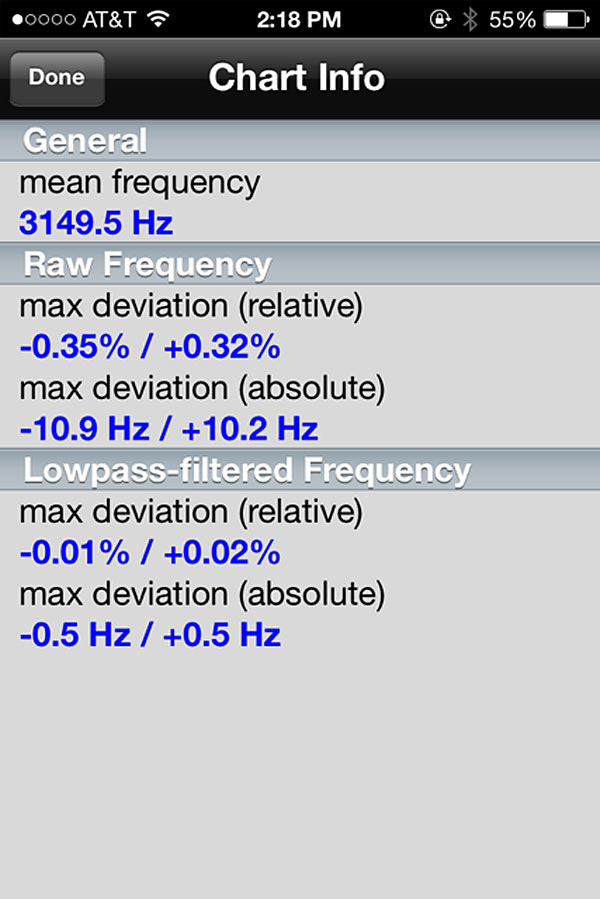

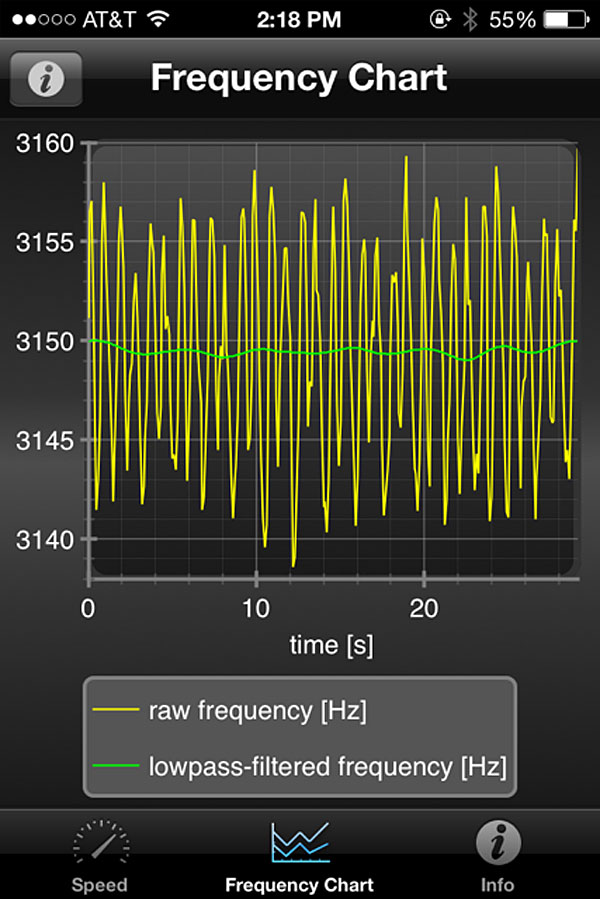

However, if you compare the graphs of platter speed variation measurements of the Pear turntables taken with Dr. Feickert Analogue's PlatterSpeed app (figs.1 and 2), with those of the Palmer last November (p.33), you'll see that they look very different, even if the measured results are similar. The Pear's graph shows greater consistency and smoothness. The Palmer's is somewhat more spiky. I'm not sure how best to interpret what can be seen, but the Pear's visually smoother graph could be the result of the bearing, the motor controller, the spiral brake, or a combination of all three.

While the accuracy of the Feickert app has not been confirmed, and it doesn't include specific figures for wow and flutter, it does provide a level playing field for direct comparisons.

Pear Audio Blue Cornet 2 tonearm

The Cornet 2 unipivot tonearm, also designed by Tom Fletcher, is 10" long and costs $2195. Its armtube is made of long-length (instead of wrapped) carbon fiber. The unipivot's range of azimuth is limited to near vertical by a roller bearing on the unipivot shaft and a pair of metal bars around which it rotates. Azimuth is set by twisting the press-fit headshell, and the vertical tracking angle (VTA) and stylus rake angle (SRA) are set by turning a threaded Allen bolt on the arm's mounting surface. Two slotted nylon grub screws lock in place the vertical POM shaft.

The unspecified material used to make the headshell is claimed to produce a tonearm "more sonically in phase." The lack of a finger lift is said to ensure proper balance and to prevent "uncontrolled resonances"—probably resulting from vibrations from the finger lift—from running "around the head shell."