| Columns Retired Columns & Blogs |

Analog Corner #316: Analog Relax EX1000 phono cartridge, Luminous Audio Technology Arion Mk.II phono preamplifier, WallyTools cartridge inspection service Page 2

As I prepared to run the Audio Relax EX1000 into the Arion Mk.II, I was thinking that it might be too much of a good thing—that the velvety-sounding EX1000 and the sweet-sounding, electronic texture–free Arion might produce an additive muddle. It didn't.

Footnote 3: WAM Engineering LLC, Tel: (707) 210-6345. Web: wallyanalog.com

The Audio Relax EX1000 (on the Schröder arm, with the OMA K3 arm/turntable) feeding the Arion Mk.II—even loaded at 100 ohms (the cartridge's 15 ohm internal impedance would suggest at least a 150 ohm load)—produced a dazzling presentation that enhanced and intensified the best qualities of both to produce among the most enticing vinyl-playback combos I've yet heard. Not that the Lyra or Ortofon feeding the Arion Mk.II didn't also sound very fine.

Considering the meticulous care that went into the design and the excellent "Made in the U.S.A." build quality, the Luminous Audio Technology Arion Mk.II should be on your under-$10k phono preamp audition list—as well as on your over $10k list, especially if you own or are considering buying the Analog Relax EX1000 cartridge.

Hands On with a Wallytools-Inspected Cartridge

Writing about something and experiencing it are very different things. A few columns back, I told you about the WallyReference tool used to level a tonearm relative to the platter and how to set azimuth to produce a repeatable "baseline" so that whenever you mount that cartridge, you don't have to go through the whole setup rigmarole. It's very useful, especially for frequent cartridge swappers.

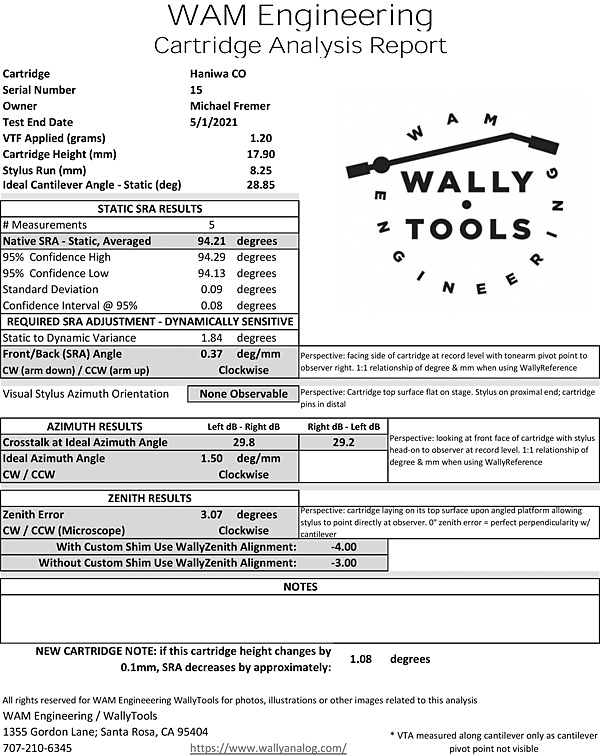

The cartridge-inspection sheet provided by WAM Engineering.

When I wrote that, I had already sent WallyTools's J.R. Boisclair the Haniwa HCTR CO Mk.II cartridge I reviewed last year. Using far more sophisticated microscopy than I have at home, he analyzed and returned it with a full report and some precisely machined shims and hardware. I'd written about this WallyTools service, which costs $495, but had not experienced it until recently (footnote 3).

If you've spent many thousands of dollars on a cartridge, wouldn't it be worthwhile to have a full analysis of what you bought before you install it, in case the build quality is off? And so that when you install it—or have it installed—you can do it so as to extract the best possible sound?

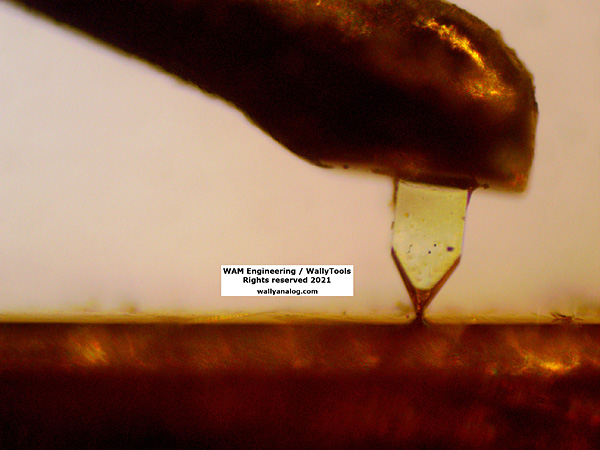

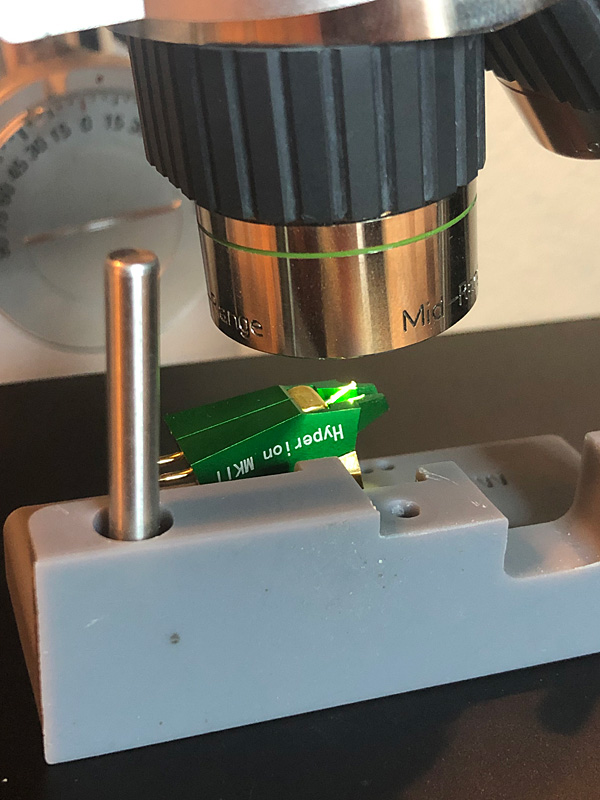

A microscopic image of cantilever and stylus for measuring SRA.

The cartridge analysis report gives you the statistically analyzed results of several readings of static SRA. Why statistically averaged? Because even the best measurements produce random variations: imprecisions. Averaging several results gets you closer to the true number. WallyTools also provides 95%-confidence-interval "high" and "low" measurements.

The Haniwa's static SRA measured 94.21° (with the arm parallel to the record surface), which is only a few degrees offrom 92°, which is a well-accepted compromise SRA setting. There's no magically correct SRA angle; cutting stylus SRAs vary, too. 92° was originally a compromise based on SRA measurements taken in the 1980s, at various mastering houses across America, and IM distortion measurements correlated with measured SRAs.

Custom shims provided by WAM Engineering for automatic SRA and azimuth adjustment.

The WallyTools report also provides a correction that takes into account how much SRA changes when a record is spinning with the stylus in the groove. This correction will be larger with more compliant cartridges. The Haniwa has very high compliance; the measured static-to-dynamic variation is 1.84°. Which means that, including the stylus drag, the SRA is 92.37°: very close to 92°.

How do you use this information? Normally, with an SRA so close to perfect, I'd just set my tonearm perfectly horizontal and leave it at that. But the WallyTools report lets you get closer. You can do it in either of two ways. The first way is to use the WallyReference kit.

The WallyZenith in action.

Install the front/back (single-blade, SRA) WallyReference on the tonearm, with tonearm height and azimuth set so that the WallyReference is resting flat on a disposable record. The WallyTools report says that the appropriate SRA correction for the Haniwa cartridge is 0.37°/mm in the clockwise direction—that is, lowering the tail of the arm, which raises the front blade off the record surface. The closest index on a WallyReference shim is for 0.375°/mm, which is close enough for anyone. Adjust tonearm height until you can slide the measuring shim under the lifted corner of the blade and the shim stops at the 0.375°/mm mark. You've just precisely adjusted SRA for your cartridge, which is not even mounted yet on the arm, without the hassle of using a microscope!

The report also includes results for azimuth error. According to the report, the ideal azimuth setting, which in the WallyTools lab produced channel separation of 29.8dB L—R and 29.2dB R—L, required a 1.50°/mm headshell (or armtube) rotation, clockwise when looking at the front of the cartridge.

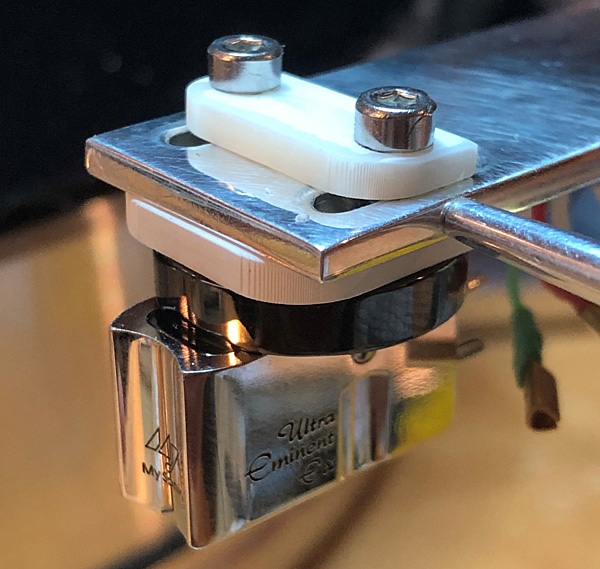

A phono cartridge mounted with WallyTools corrective shim.

Install the left/right (azimuth) axis single blade WallyReference. A 1mm lift at the corner of the WallyReference blade equals 1° of azimuth change. Adjust your azimuth mechanism until you can slip the measuring shim under the raised corner of the WallyReference and the 1.50°/mm mark comes to rest under the corner of the blade. Tighten everything and you're done.

However, if you're using a "straight pipe" tonearm, with the offset angle at the headshell, rotating the headshell or armtube to set azimuth also changes SRA. For every degree of azimuth change, SRA changes almost 0.5° on 9" tonearms and 0.33° on 12" arms. WallyTools offers an online calculator to help you figure this out, for any tonearm effective length.

Now remove the WallyReference and install your cartridge. Set the tracking force roughly, adjust overhang, do the final setting of the tracking force, and set the antiskating force.

You've precisely set up your cartridge without a microscope or an oscilloscope.

A cartridge under the microscope at WAM Engineering.

Your $495 cartridge report provides one more piece of information: your stylus's zenith angle error. This wasn't a problem in the old days, when styluses were round, or close to round. But today's aggressive stylus profiles need to line up in the record grooves to perform at their best. Unfortunately, even on costly cartridges, the zenith error can be large, sometimes too large to compensate for. Those cartridges should be returned for replacement—but how you know? Now there's a way.

The Haniwa's cantilever/stylus assembly, which, like many cantilever assemblies these days was supplied by the Ogura Jewel Industry, was off by 3.07°. That's not a small amount, but it's correctable with the WallyZenith tool, which allows you to compensate for the cartridge's zenith error when aligning your cartridges: Instead of aligning the cantilever, with the WallyZenith, you're aligning the stylus itself. With that accomplished, cartridge setup is complete.

But there's an even easier way! When you send your cartridge in for evaluation, WallyTools provides a custom shim. When installed, this little shim automatically compensates for variations in your cartridge's azimuth and SRA. Here's how you use it.

First, install the cartridge and set the tracking force, just so that you can accurately measure the distance from the bottom of the headshell to the record surface. There's no need to set overhang. Now, remove the cartridge and install the WallyReference, adding shims as needed to duplicate the measured distance between the bottom of the headshell and the record surface. Adjust the arm height and azimuth until both WallyReference blades rest flat on the record surface. The tonearm would now be perfectly set up—if the cartridge were perfect. It isn't of course.

Now remove the WallyReference and shims and install your cartridge with the corrective shim from WallyTools. Set overhang, (final) tracking force, and antiskating. If you wish to compensate for zenith-angle error, correct the overhang adjustment with the WallyZenith tool. You're done.

I was able to precisely set up the HCTR CO Mk.II in about 15 minutes without a microscope or oscilloscope and without having to do much adjusting or calculating. By taking note of the arm height setting, I could swap out cartridges in minutes by adjusting height, changing shims, and setting overhang, tracking force, and antiskating. What's more, I could remove the cartridge on an SAT headshell, set up a few more cartridges on other headshells, and switch among them in a minute or two.

Two notes: Some arms, like those by Rega and SME, don't offer adjustable azimuth. But the hardened shim you get with your cartridge analysis sets azimuth automatically. The $95 WallyFulcrum, too, lets you adjust azimuth, but you'll have to measure crosstalk yourself.

Finally, WallyTools's J.R. Boisclair is a Kuzma 4Point owner. If you own a Kuzma 4Point and send him your cartridge for analysis along with a 4Point headshell, you'll get it back with overhang and everything else set so all you have to do is set tracking force and antiskating. Franc Kuzma and American importer Elite A/V Distribution are way down with this!

How did the Haniwa cartridge sound after being set up automatically with zenith-angle compensation? Tracking well at 1.2gm, it sounded as liquid and effortless as I remembered it sounding. I cannot say if the zenith correction produced a noticeable difference because I didn't have time to reset it to normal and do an extended A/B comparison before deadline. Maybe next time.

Footnote 3: WAM Engineering LLC, Tel: (707) 210-6345. Web: wallyanalog.com

- Log in or register to post comments