| Columns Retired Columns & Blogs |

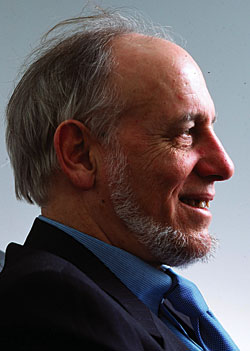

Tim de Paravicini: King of Tubes

How many hi-fi professionals can say that they've designed at least one of every part of a complete recording system, from microphones to tape recorders to vinyl-disc-cutting electronics? Probably only Tim de Paravicini (footnote 1). Best known to audiophiles for his extraordinarily durable EAR valve amplifiers, Tim is also an electronics guru to the professional recording world. His global reputation today is based on more than four decades of making things better, building equipment that stands the test of time.

Footnote 1: Tim was last interviewed for Stereophile in September 1990.—Ed.

In the 1970s, Tim spent four years as chief amplifier designer for the prestigious Lux company in Japan, coming up with such models as the classic high-end C1000 preamplifier and M6000 power amp. In Japan, too, he met his wife, Oliva, who taught him Japanese while he taught her English. Returning to the UK, he set up his own company, EAR (the initials originally stood for Esoteric Audio Research).

In the 1970s, Tim spent four years as chief amplifier designer for the prestigious Lux company in Japan, coming up with such models as the classic high-end C1000 preamplifier and M6000 power amp. In Japan, too, he met his wife, Oliva, who taught him Japanese while he taught her English. Returning to the UK, he set up his own company, EAR (the initials originally stood for Esoteric Audio Research).

In the 1980s, Tim designed and built his first complete system of record-cutting electronics, for Island Records; as a consultant, he designed the hugely successful A1 integrated amplifier for Musical Fidelity. By the 1990s he was rebuilding Studer and Ampex analog tape recorders for ultimate-quality studio mastering. At hi-fi shows one year he used master tapes from Pink Floyd to demonstrate his astonishing "direct drive" Quad electrostatic loudspeaker—in which the high voltages for the electrostatic panel came directly from the tubes of his special amplifiers.

In the present decade he's added a turntable, CD, and loudspeakers to EAR's Yoshino line of domestic products, while continuing to take on major projects for professional clients—for example, a disc-cutting system for Mobile Fidelity Sound Lab. He's also acted as a design consultant to Quad for the new QC24P tube phono stage and the II/80 tube power amp.

But it all began at the dawn of the 1960s, when, like most teenagers in England, Tim heard rock'n'roll for the first time. He also learned to play the drums.

"I was a boy in Nigeria, but then I was brought to England to be educated. Did the usual thing—school, college—and then I went off to South Africa. But even when I was at school I was involved with bands in one form or another. It's a kind of addiction, rock'n'roll. I first saw it when I was about 12 or 13, and that was the holy grail. I was brought up with classical music, my mother loved to play classical music, but I was at the age where I didn't want that.

"Of course, the other notable at my school in Stevenage was Ken Hensley of Uriah Heep. I think, even at the age of 13 or so, I was able to see that this guy had the push, the determination, he wasn't going to rest. You've got to have that spark or fire by the time you're 15 or 16, some sort of drive to keep you going. I suppose that was my guiding light.

"The other thing was poverty. Necessity is the mother of invention. If you haven't got the money, you can't just go and buy the nice toys, you have to make them, and that puts you in good stead to learn how to do these things the hard way.

"In South Africa at that time [the late 1960s] there was no television, so hi-fi was very much broader-based, and (white) people who had disposable income were buying even the B&O class of hi-fi. So at that time there were more McIntosh amplifiers there per head of population than there were pretty well anywhere else. It was luxury having no television, in a sense!

"I worked for myself, and for a couple of hi-fi stores and a couple of studios in Jo'burg, and I did repair work and consultancy for one of the stores that imported McIntosh and Luxman and other high-end brands. It was there that I met the guys from Lux, who were on a sales trip, and they offered the invitation to go to Japan.

"I'd been in South Africa for seven years, I'd done this, that, and the other in hi-fi, been involved in rock groups, with PA systems and so on. So, not just domestic hi-fi—I'd been involved in audio from the microphone to the loudspeaker. I just wish more people who listen to hi-fi understood what goes on at the front end of it all before they pontificate about the quality of recordings—and realize that a lot of them are compromised badly.

"Anyway, in Japan...the Japanese have always aspired to quality. At Lux I luckily had the ability to do what I more or less wanted to do—occasionally they would ask me to develop or design a particular product, but it was usually a consensus. And one or two of the products have become classics in their own right. For example, there was the MB3045 amplifier, a 70W transistor amp. Then there was the C1000, and the M4000 and M6000 amplifiers. Even Robertson-Aikman [the late Alastair Robertson-Aikman of SME] had them at one time.

"I was quite pleased it all happened, really. I was never happy with mediocrity, and I don't think that I could have ever persuaded a British company to go to that measure. If I look at Peter Walker with Quad, he started off being at the top end of the market in the 1950s—the Quad II and 22 were among the best half-dozen amplifiers in the world—but as time went on, through the transistor generation, the 303 and then on to the 405, they slipped down the ladder. They lost that aspirational position at the top. The Quad Electrostatic was the only speaker that was at the top of the ladder, and it still is at the top! But as far as electronics were concerned, they missed it. The problem with British companies was, of course, the lack of investment at that time—although Quad were better than most, which kept them ahead. But the Harold Leaks of the world didn't invest in new products. But the time I was in Japan, the mid-1970s, was a time when Japan was prospering very well, and was prepared to take risks and gamble on things. If a company could see that they would make a minimum ultimate run of 10,000 units, it was worth going for.

"Fortunately, we had a couple of very good industrial designers. We could discuss it and come up with what we wanted, and they would interpret it and come up with a clay model. Lux built everything in clay as a dummy model before actually committing to putting a complete product together in the proper sense. And it's that detail, subtlety, that quality. I'd love to try and emulate that with my own products, but with the best will in the world, I don't have the capital to do the swish tooling. But I still try to keep an air of quality with my products.

Footnote 1: Tim was last interviewed for Stereophile in September 1990.—Ed.

- Log in or register to post comments