LATEST ADDITIONS

This You Must Read

Having visited China and witnessed the building boom firsthand, I must admit that I suspected corners were being cut in construction—so I wasn't surprised by how many buildings came down. Considering all the construction accidents happening in NYC this year, who am I to look askance at China?

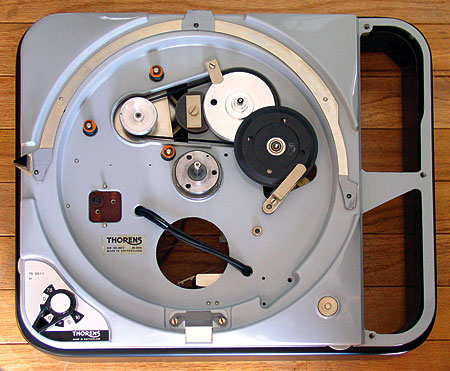

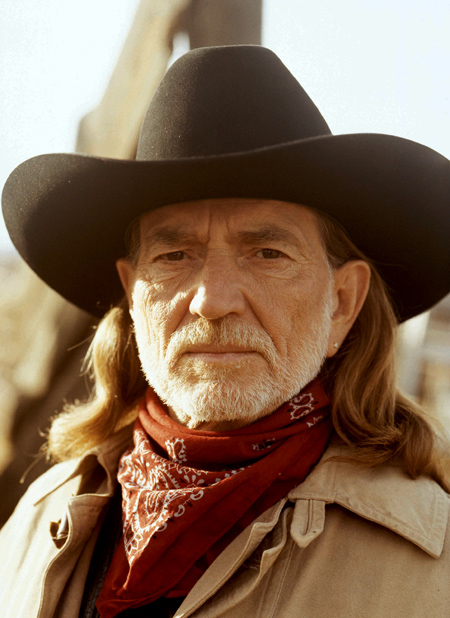

Shotgun Willie

Stephen Mejias, our excellent assistant editor, is fully in the grip of vinyl fever. He and I are now having daily conversations about the once and future allure of the long player.

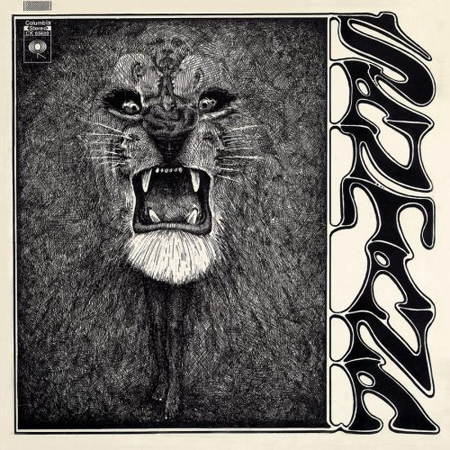

A Dirty, Dispensable Record

I never cared much for Santana. (The band, not Johan. Johan, I love.) You know, there was always "Evil Ways" and "Oye Como Va"—fine songs for a stretch of highway when there's nothing else on the radio, but, eh: So what? I shrug my shoulders.

Road Trip!

Back in April, Daniel Jacques of Audio Plus, Focal's North American distributor, invited me to visit Focal's factory in St. Etienne. Since I'd never reviewed any Focal loudspeakers, I didn't know a lot about the company, but I <I>have</I> spent many happy hours in Jonathan Scull's ribbon chair, listening to his Grand Utopias, so I was eager to go—and to learn more.

On the Factory Floor

Focal combines high-tech work stations with a phenomenal amount of hand labor. Metal drivers and inexpensive dome tweeters are heavily automated, but many drivers are assembled by <I>hand</I>, especially Focal's "W" composite cones.

First the Foam

Stiff, extremely light "aircraft" foam is stretched over a mold by hand and gently heated to maintain "dimensional stability," according to Dominic Baker, Focal's export sales director. The molds have different flares, depending on the driver's purpose—and they are produced in-house by Opus 42.

Then the Miracle Fabric

Another hand process is stretching and fitting various layers of adhesive-impregnated glass-fiber material to the front and back of the foam center. Again, depending on the driver's purpose, different amounts of glass fiber layers are employed. Since Focal controls the flare, drive system, and crossover, the company has massive amounts of control over elements like mass and Q.

Magnetic Personality

One of Focal's core technologies is its use of "multi-ferrites," Mahul having realized that it was more precise to use multiple magnets in big drivers than it was to rely upon finding enough truly huge, uniform magnets.

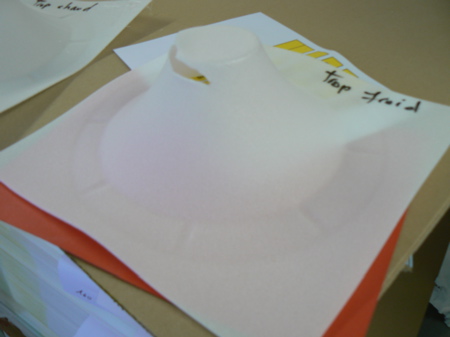

Top Secret

Focal allowed me to visit the Be facility in which it manufactures its beryllium tweeters in a HazMat room. They would not, however, allow me to take photographs within it—saying that some of the machines were secret. So they gave me this factory authorized image of their technician examining a completed tweeter.