| Columns Retired Columns & Blogs |

Listening #40

Not only is it possible for a thinking person to now and then drastically change his point of view, if for no other reason than the sake of change—if one wishes to prevent self-seriousness and various other forms of mental decay, it's probably an outright must. So it was that I recently began to wonder if everything I know about record players might be wrong.

Footnote 1: In the early 1990s, Naim Audio's then-distributor in Germany considered the basic TD 166 design so good that they used it as the platform for a well-regarded turntable they called the Phonosophie P1.

Some background: Because I didn't stumble on the whole perfectionist audio scene until 1979 or so, and because I'd already built a decent record collection by that time, I was an easy convert to the gospel of Rega and Linn: Their turntables sounded better to me than all the others I'd heard, and the technical explanations their adherents drew on in promoting such things as the Planar 3 and the LP12 made sense. Thus, it wasn't long before these tenets became part of my own belief system:

• Small motors are better than big motors, because small motors give off less noise and vibration—simple. Big motors have the advantage of greater torque, but I have yet to be convinced that anyone really needs it.

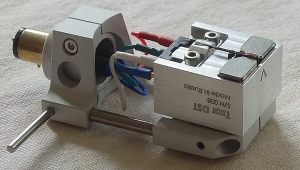

• Belt drive is superior to other methods of driving the platter because the rubbery belt tends to filter, rather than transmit, vibrations and noise that come from the motor. By contrast, direct drive rather foolishly puts the platter, and thus the record, into intimate contact with the system's most conspicuous source of vibration. For its part, idler-wheel drive—in which the motor pulley drives a rubber wheel, which in turn drives the inside rim of the record platter—doesn't go far enough in isolating the one from the other; besides which, it's hard to find an idler wheel sufficiently round and well-balanced to drive the platter as smoothly and consistently as required.

• In any record-playing system, if the platter and the tonearm are subjected to any manner and degree of movement—and they will be, of course—then they must be connected together so that they move together, as a unit and in isolation of everything else, because relative movement between the two will limit or distort the information retrieved from the groove. Usually the most effective approach is to use a suspended subchassis, whereby the platter's main bearing and the tonearm's mounting platform are both rigidly fastened to a piece of something (metal, hardwood, laminate, polymer, wartever), and whereby that thing, which we'll now call a subchassis, is hung from or perched on springs of some sort. Thus the working bits are isolated from airborne vibrations, structure-borne vibrations, and vibrations from the motor (pace Pink Triangle, who plunked their motor right on top of their subchassis, but got away with it because it was a small, low-torque DC motor).

• For more or less the same reasons as the above, the materials used in making a record player's platter, subchassis, and even tonearm must all be at least somewhat similar to one another in how they respond to vibrational energy: the rates at which they store and release energy, the frequencies to which they're most responsive, and so forth. Everything on God's Great Earth resonates, despite our best efforts to the contrary, so it makes a great deal less sense to fight it than it does to let it occur in a controlled fashion—with every part of the system behaving the same way, and so preventing relative movement between parts. Thus, having an aluminum platter, subchassis, and tonearm makes more sense than having one of those made of aluminum, another of wood, and still another of plastic—and makes a hell of a lot more sense than the amateurish application of this or that damping goo to only one part of the system. In fact, that's pretty stupid.

That's my credo, and for a long time I stuck to it. Every now and then I allowed it to bend a little, especially in response to products that sounded magnificent, even if one or two elements of its design challenged my belief system—the original Voyd and its three high-torque motors, the Pink Triangle Anniversary and its plastic platter, the VPI Scout and its massive, well-damped chassis—although my soul-searching never went too terribly far. That was probably because I was always able to explain away certain things, such as the fact that the Pink Triangle sounded better with the internally damped SME V tonearm than with the undamped Naim Aro or Linn Ekos arm. That only seemed to support my point of view.

But to hell with all that. Have I ever told you the boot story?

The Boot Story

Between 1978 and 1980, I worked as the equipment editor of Backpacker magazine. Part of my job was commissioning reviews, usually in a multiproduct survey format, of such products as sleeping bags, tents, outdoor stoves, and hiking boots—but just as often I wrote those reviews myself. And remarkably or not, taking the products out of my office and into the great outdoors was not always a part of my reviewing regimen.

All of our reviewing parameters were based on theory rather than practice, and had been written down for my benefit by the magazine's founder and preserved for all time in a binder covered with a sort of a faux denim with bright orange stitching. Testing a tent, for example, did not necessarily involve spending more than a few minutes inside the thing, but instead required that I make note of the quality of its fabric by counting the numbers of threads in a square inch of it—that and counting the number of stitches per inch on its seams, weighing it, and observing how much time was required to set it up.

And so it was for boots: The founder believed that exposed seams were bad, so my first job was to simply look at the boot and deduct a certain number of points for every inch of such seamwork I found. The founder also believed that a certain number of eyelets for the lacing was the right number, and likewise a certain sole thickness, heel height, style of scree collar, and, most important, a certain means of fastening the uppers to the soles.

One year I did a boot survey. Most of the review samples I received were expensive, handmade things from small, specialist companies run by "hippies" who usually turned out to be greedy, mean-spirited, capitalist pricks whose long hair and Sonny Bono vests were simply part of a disguise. But one pair was from the then-new, already successful company Timberland. I knew from the moment I saw them that Timberland's hiking boot, with a sole that was injection-molded rather than stitched onto the uppers and its several inches of exposed seams, would flunk all the tests we'd worked out and get a very poor review. Which it did.

Because its founder had once been taken to court by an irate equipment supplier, Backpacker had a policy: Whenever it appeared as though a product was about to get a stinky review, we went out of our way to buy the review sample, at whatever price, from whomever supplied it, so we could always have it in our possession. The reason: In the event that a lawsuit came our way, we would need to supply proof that the product sent to us did indeed fall short of our objective, consistent standards.

So we bought those Timberland hiking boots. And because they were size 9½, and because I was the only one in the office who wore that size, I got to keep them.

The punchline of The Boot Story: I wore those boots every fall and winter after that, paying absolutely zero attention to maintenance of any sort, and they fell apart only last year. Those Timberland boots, which got one of the lowest review scores in the history of Backpacker, lasted for over a quarter of a century, during which time they were unfailingly comfortable and supportive. And they never failed to impress the ladies, especially when worn with faded jeans and a snappy blue blazer.

Which reminds me: Have I ever told you The Thorens Story?

The Thorens Story

There isn't much to this one. I used to own a Thorens TD 160—one of their less expensive turntable-tonearm packages—until the day I lost track of my senses and traded it in on a direct-drive Denon. About a week later, I began to wish I had the Thorens back.

On those occasions when I lie awake at night, luxuriating in the memory of a thousand awful screwups, I wonder why I didn't just keep my Thorens, or maybe trade it in toward their altogether more refined TD 166 (footnote 1). But back then I still didn't know that some turntables actually sound better than others, and I suppose I was too caught up in the quest for convenience features, along with the misguided notion that this year's mass-produced tonearms would be gentler on my records than last year's. For those reasons and more, there was nothing else in the Thorens line that I aspired to own—and by the late 1960s and early 1970s, the company had, in every sense, moved far away from their own expensive and substantial onetime flagship, the TD 124.

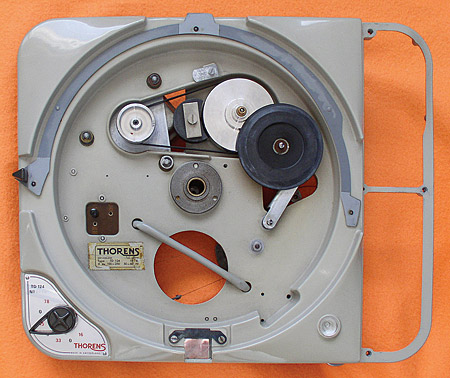

For some folks, the TD 124 was and is the Thorens to have.

Perhaps you saw a couple of them when your class made that field trip to the local radio station, or maybe there's one gathering dust and Hantavirus in your local Goodwill shop. Whatever the setting, then or now, the TD 124 is unmistakably a superior-looking piece of gear. Not even its ribbed rubber mat or charmingly dated control knob can detract from the seriousness of the Thorens' intent or the quality of its execution.

The Thorens TD 124 was introduced in 1957, some three years after the debut of that other flagship turntable, the Garrard 301. Like the Garrard, the TD 124 was a motor unit: a component rather than integrated turntable, whereby the user had to supply his or her own plinth, not to mention tonearm and cartridge. The two turntables are outwardly similar, although the Thorens, with its 10-lb platter and integral tonearm board, is heavier and somewhat larger overall.

The Thorens' idler-drive system is also significantly more sophisticated than that of the Garrard 301: The TD 124 puts a 2.75" belt-driven idler pulley between the motor pulley and the idler wheel, rather than let the former directly turn the latter. The designers' intentions are lost to us, but Thorens' approach could be seen as part of an effort to keep motor noise from "leaking" through to the platter, and not just a vulgar display of Teutonic engineering might (although it is that, too, I suppose).

Footnote 1: In the early 1990s, Naim Audio's then-distributor in Germany considered the basic TD 166 design so good that they used it as the platform for a well-regarded turntable they called the Phonosophie P1.

- Log in or register to post comments