| Columns Retired Columns & Blogs |

Graham Model 2.0 tonearm

When Bob Graham introduced his 1.5 tonearm at the end of the 1980s, many thought he was dreaming: Vinyl was going the way of the console radio—who would invest two-grand-plus in a tonearm? But there was a method to Graham's madness—he'd designed his arm to be a drop-in replacement for more than 20 years' worth of SME arms, all of which shared the same mounting platform. Perhaps, in his wildest dreams, Graham had already envisioned the current "analog revival"—but even without it, he figured there'd be a robust replacement market, and he was poised to exploit it with what he thought was a superior product.

The Graham is a deceptively simple inverted unipivot featuring a cast-ceramic armtube (tube within tube) of relatively small diameter. (An aluminum armtube is available at lower cost.) The build quality of the arm is superb, with the Graham having a sophisticated, "finished-product" look. It offers complete control over every setup parameter.

While Graham has upgraded his arm over the years, the 2.0 represents the most extensive change he's made to the design. The most significant difference between the 1.5 and the 2.0 is the mounting platform. Gone is the sliding-micrometer SME mount, to be replaced by a far more rigid three-screw round mount. Of course, the SME mount is still available for SME owners wanting a drop-in replacement, but I'd recommend getting a new armboard to take advantage of the improved sonics the new mounting system provides.

In fact, Graham now manufactures sophisticated constrained-layer-damped armboards from aerospace materials for VPI TNT and Aries turntables. Graham also manufactures a Linn armboard, and the 2.0L: a special arm for Linn LP12 owners that incorporates a different pivot housing and output connector compatible with the Linn suspension. The 2.0 under review came mounted on a Graham board for the TNT.

The VTA adjustment system's clamping mechanism has undergone a significant upgrade as well. Other 2.0 changes include a new, more massive main pivot housing (now made of tungsten), a stronger and sturdier VTA adjustment drive, a new "fine-tuning" adjustment scale, and a minor change in the main housing geometry to provide for greater lateral stability. Graham has also refined his ceramic armwand (when this was first introduced, the 1.5t became the 1.5t/c), using a denser ceramic material while embedding in the outer tube a metallic substrate that allows the tube to be electrocoated for both a better-looking finish and improved electromagnetic shielding.

The "whys" of these changes? While the 1.5t has also received uniformly enthusiastic reviews around the world, its bass extension suffers now in comparison to other, more recent designs such as the Immedia and VPI JMW Memorial arms. Also, while the Graham's design allows for VTA adjustment during play, once the arm went into production, tolerances could not be maintained quite as exquisitely as Graham would have liked. So while loosening the VTA-adjustment locking screw on my review sample back then didn't affect the arm's stability, loosening it on a later-production sample I received "popped" the arm, tilting it slightly to the side—not a good thing! Some samples did this, others didn't—but clearly, the problem needed to be addressed. Also in need of attention was the locking mechanism itself, which, when tightened, presented a small surface area to the shaft.

Basic design

Because this arm has been extensively written about over the years, I'll limit my coverage here to the design aspects that I feel affect its performance.

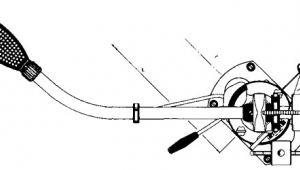

Graham's design features an inverted unipivot: the Swiss-made polished tungsten-carbide tip, machined to an accuracy of five decimal places, screws down into the silicone-damped bearing housing, causing it to come into contact with the cup half of the bearing. While the "male" part looks more rounded than those of some other bearings, the contact area is still a single, tiny point. Its shape means that, when the arm rides up and down on a warped record, it "rolls" smoothly. The Graham's bearing housing is in a direct vertical line with the turntable chassis and mounting plate.

In Graham's improved design, the vertical shaft upon which the bearing sits is held in place via a substantial locking-collet system. When the locking screw is backed off, while the shaft remains in the grip of the collar, it can be easily and smoothly screwed up and down to adjust VTA during play. Securing the locking screw causes the collet to firmly grip the shaft around its entire circumference—a major structural improvement over the 1.5t.

The Great Debate

In order for a tonearm to hold the cartridge rigidly in place while allowing it to move both horizontally (to track the groove spiral) and vertically (to deal with the inevitable warps), the bearings must be both rigid and friction-free—almost a contradiction in terms. Which bearing system, fixed or unipivot, is better able to accommodate the seeming contradiction? Here analog fans take sides. Fixed-bearing devotees argue that because unipivots can move about seemingly infinite axes, they are unstable under dynamic conditions. Unipivot fans argue that once you've loosened a fixed bearing enough for it to move at all, you've introduced the inevitable "bearing chatter," which translates into friction, noise, and unwanted movement.

Which side is correct? Like all things in life, each argument has its strengths and weaknesses. In my experience, both systems, properly executed, can work equally well. (I hope you don't take that as a cop-out.) One thing I will not tolerate in a tonearm, pivoted or linear-tracking, mechanical or air-bearing, is bearing "slop." It doesn't make sense, and it can't make for accurate extraction of the information in the grooves, period. As with a high-quality fixed-bearing system, a properly designed unipivot does not exhibit unwanted movement under dynamic conditions.

- Log in or register to post comments