| Columns Retired Columns & Blogs |

twenty_eight_thousands_dollars.... That is a lot of money.

By the way, the mounting plate looks like a stock Jelco part.

So there I was in Las Vegas, at the 1983 Consumer Electronics Show, schlepping heavy bags filled with press kits, each containing an audio cassette of a dozen radio commercials for a car-stereo store that I'd voiced and produced, along with a résumé-bio and endorsements from clients.

Back then, car stereo was king. I walked around a huge exhibition hall filled with tricked-out cars, reading nametags. When I spotted one that read "FRED'S CAR STEREO, FARGO, ND" or "CAR STEREO SYSTEMS, SEARCY, AR," I accosted its wearer, made my pitch, and handed him a press kit. I'm sure most of those kits were tossed in the trash minutes later.

It was humiliating, and the rejections were rough on the ego, but it worked. I acquired enough clients to pay the bills and grow the radio-ad business I'd mostly abandoned when I moved to L.A. in 1979, to work on the film Animalympics (1980). So when, at an audio show, I'm accosted by an up-and-comer who can't afford a room or a booth, or who knows no one with whom he might even share an exhibit space, I try to be welcoming, and to at least listen to the spiel.

That's how I met Marc Gomez, of Swedish Analog Technologies (SAT). He approached me as I walked the show floor of High End 2014, in Munich, big black Pelican Storm case in hand. "Let me show you my tonearm," he said—not everyone's heard that, um, pickup line.

He hoisted the case atop a table, and opened it to reveal a massive tonearm prototype that looked almost larger than life. An SME V on steroids, I thought. As Gomez talked, it became obvious that I was staring at a very serious, well-thought-out design that was more about perfecting the known basics than inventing new ones based on questionable flights of fancy. Also obvious was an exquisite level of engineering precision and attention to detail. Gomez made clear that his goal was not to produce a musical instrument capable of "sonic beauty," but rather a precision playback device devoid of a sound of its own—or, as Rockport Technologies' Andy Payor once described the ideal tonearm, "a reverse machine tool." Our encounter ended with my usual "Of course, I'd like to review it, blah blah blah."

My last words to Gomez took on greater import back in my hotel room, when I visited Swedish Analog Technologies' website. There I learned that he'd earned an MS in mechanical engineering and materials science, and that he was born in Barcelona, Spain, in 1972, and moved to Sweden in 1999. While tonearm design isn't exactly rocket science, Gomez's résumé includes, among other design and development projects, the engine for Europe's Ariane rockets, as well as work on Porsche's Carrera GT, Rolls-Royce's water-jet engines, and components for Volvo and Saab.

But after years of working on projects for others, Gomez decided to start his own business, and in 2010 chose to begin designing a tonearm—something that makes complete sense to me, though perhaps not to those still uninitiated into the Ways of Analog.

Not Magic, but Science

Gomez designed the SAT tonearm with the same computer-aided design and engineering tools he uses in his day job—much as Continuum Audio Labs' design team did when devising the Cobra arm. However, while the Cobra is made using 3D printing, Gomez leveraged his experience in the development and manufacture of composite materials to achieve his goal of high levels of rigidity and internal damping.

And, as did the Cobra's designers, Gomez decided on a 9"-long arm; he felt that this length provided high rigidity while keeping the arm's moment of inertia at more manageable levels, that the increase in tracking distortion produced by a short arm was "marginal," and that the inherently greater rigidity of a 9" arm would more than compensate for the slight increase in lateral tracking error.

On the SAT website's "Technology" page, Gomez describes in great detail the costly, labor-intensive process required to produce the laminates used in the SAT arm, and the differences between the carbon-fiber composites he designs and manufactures and the thin walls of typical carbon-fiber armtubes, made of woven fiber, or with fibers that run only along the tube's longitudinal axis.

Gomez asserts that his laminates achieve much higher specific stiffness than any material used by other makers of tonearms, and claims that his armtube's first resonant frequency (not the same as the arm/cartridge system's resonant frequency) is 3.0kHz—which, he says, is also far higher than that of most tonearms. More important, he says, the amplitude of that resonance is extremely low.

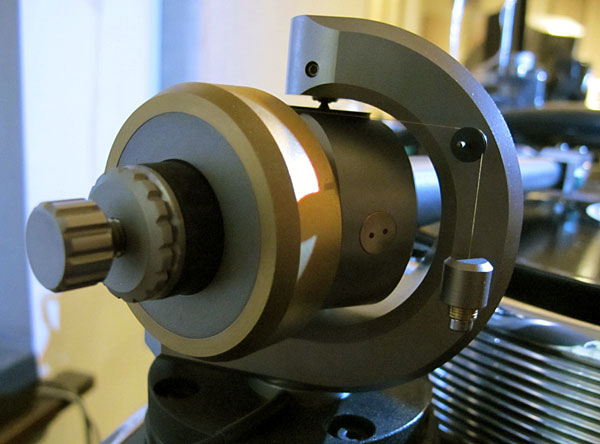

Though Gomez chose to prioritize performance over appearance, the SAT arm, dominated by its massive horizontal bearing yoke of stainless steel, is nonetheless visually appealing.

Description

The SAT tonearm's tapered armtube is made of pre-preg carbon fiber (ie, composite fiber material that has been pre-impregnated with a resin), cured by heat and pressure in an autoclave. It is manufactured in a single piece, from the headshell connector to the counterweight stub. A polymer sheath provides outer damping; three additional damping methods are applied inside the tube. Gomez says that carbon-fiber composites, and even wood, have significantly higher internal damping than metals such as aluminum, magnesium, titanium, or steel.

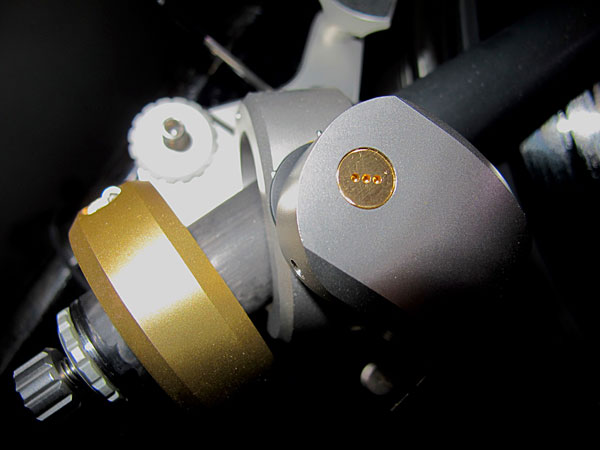

The SAT's unusually thick but lightweight headshell is built up from about 40 carbon-fiber plies. It's detachable, and can be rotated to adjust azimuth using the arm's reference marks: one on the headshell, three on the armtube. But while the headshell can be removed, there is no signal break where it joins the armtube, or anywhere from the cartridge clips to the low-mass, WBT NextGen RCA plugs. As in the Kuzma 4Point arm, the SAT's wires and cartridge clips exit a front opening in the armtube.

The SAT's standard cabling is a 1.2m length of instrumentation-grade, silver-coated copper conductor insulated with PTFE (Teflon). Other lengths, and types of cable and connector, are available on request. And for those who prefer absolute rigidity, and are willing to forgo the ability to adjust azimuth and the convenience of exchanging headshells with cartridges pre-mounted, Gomez offers the option of a fixed headshell.

The bearings are large-diameter, tungsten-carbide pivots resting on sapphire v-jewels. SAT includes a special tool so end users can adjust the vertical and horizontal bearings before loading, to eliminate any slack while keeping pre-loading friction low. This means that the arm can be custom tailored to produce tighter coupling or lower friction, depending on the cartridge's compliance. Or, as is often the case when audiophiles gain control of critical adjustments—as when speakers come with easy ways for the owner to adjust their tweeter and midrange levels—they can royally screw things up. I'm not sure it's a good idea to give obsessives control of such critical adjustments.

The SAT arm is dynamically balanced: Its vertical and horizontal rotational axes are both at the arm's center of gravity, which means that any angular acceleration around one axis will induce no torque in the other axis. When the arm rides a record warp, the cartridge's cantilever will not be deflected to one side.

Despite the high-tech materials, operating and adjusting the SAT arm are more traditional. The antiskating mechanism is a filament/weight system, the filament's looped end fitting over a tiny rod that protrudes from the side of the horizontal bearing housing, which is shaped like a flattened O. The filament rides on a thin, grooved cam attached to the top of this housing, then over a tiny wheel riding on an axle of equally small diameter protruding from the rear of the vertical bearing housing. A small weight attached to the free end of the filament produces the antiskate force. Supplied washers can be attached to the weight to increase the antiskate force.

But while the antiskate system's mechanics look traditional, Gomez says his design maintains "constant torque" across the entire surface of the record; many other system, he says, do not follow the actual geometrical variation of linear offset as the arm traverses an LP. While skating is affected by many uncontrollable factors—eg, degree of groove modulation, vinyl formulation, stylus profile, tracking force—Gomez says that consistency of antiskating torque across the entire LP side is still desirable and achievable.

The C-shaped vertical bearing yoke attaches to a massive stainless-steel pillar 40mm in diameter that is clamped within an equally massive aluminum base. Adjustments of vertical tracking angle (VTA) and stylus rake angle (SRA) are both made via a recessed, large-diameter screw with a knurled, indexed wheel, whose pointed bottom rests on the base.

To adjust VTA/SRA, loosen the base clamp. Turn the knurled wheel to raise or lower the arm pillar, then fix it before reclamping the arm. Numbers silkscreened onto the pillar allow you to accurately return to any previously selected height.

twenty_eight_thousands_dollars.... That is a lot of money.

By the way, the mounting plate looks like a stock Jelco part.

Crotchety old guys like you are why I don't publicly admit I'm an audiophile, and that I get embarrased when my wife outs me. I mean, I love a good system as much as the next sucker, and I put in a couple of hours a day on my Line Magnetic amp, DAC, and Devore O93s. But I'm not a dick about it when I meet someone who's equally in love with the $75K Magicos they just bought. Right now, as I type, I'm listening to the new Father John Misty album, through those same O93s, on the 1956 Garrard 301 that I bought for cheap and rebuilt with the early 1960s SME 3009 I also rebuilt with brass counterweights, and that's sporting an early Shure M7D running at 3.9g on an 18g headshell. You know what? It sounds flippin' amazing. Now, I'm generally a skeptical guy when it comes to emporers' clothes, but I'd say the record sounds better than the downloaded version I also got. But would I call somebody a stupid moron for throwing down on a new Brinkmann Spyder and a Miyajima Zero just so they can listen to reissue Beatles mono records? Eh, only if I absolutely have nothing better to do with my life. Because music is fun, and transformative. And if that's not the case for you, too, why bother trolling an audiophile editor?

No amount of money will make your mp3 files and CDs sound better than my vinyl rig....Too bad for you

No amount of money will make an LP sound as good as a CD from the same source, assuming both are properly mastered.

The same source?? The recording is digital 24bit file, when mastered for vinyl pressing the same 24bit master file is used to press the vinyl. That 24bit file is truncated down to redbook 16/44.1 for CD pressings, thus music is lost, meaning the CD version is well, not good.

Wrong. The music is lost making the LP, dumbass.

I have many CDs that were duplicates of LPs, including many ECM recordings made on tape originally. The CDs are better. Remember, I had a Stax CP-Y cartridge. Better than that there was none. I also used a Magnapan unipivot tonearm, and a Thorens TD-125 Mk II table. This set-up was awesome. But the CDs are better.

I had 1200 LPs and a first-class setup! Don't tell me I don't know about LPs. You're a reprobate and a loser. I had some of the best records ever made, and I sold all of them, and said good riddance! And it's not 'vinyl', dumbass! Did you know that vinyl is colorless, and that the black added to it makes it noisier? Did you know that since 1969 there have been no true stereo LPs? That was when 'compatible stereo' was introduced. Frequencies below about 500Hz are mixed to mono to reduce vertical modulation, improve non-fill and running time. It also allowed mono cartridges to be used with less damage to the LP. This is why there was a 'mono' Beatles White Album, but no 'mono' Abbey Road. Compatible stereo made mono records obsolete. But of course I know nothing. You're a total dumbass.

And I have no interest in debating with deaf mental cripples.

28 Thousand is a bit rich for a tone arm.

(They eat a lot of fish)

The "S" SME Series 2 tonearm is the best I've heard.

It was cheaper, and I could park it and not worry about dents.

(Nothing fishy, there)

The Swedes 15 years ago made our Submarines ; underwater they sound like a rock concert.

(That's fishy)

I so much better than the SME. Find my YouTube channel and even digitally compressed you can hear it.

...all the compromises have been worked out of the tone arm design problem. Well, anyway I hope so.

What a beautiful piece of engineering. I had thought William Firebaugh had had pretty much the final word on how to think around the tone arm's sand traps. I can afford Mr. Firebaugh's work, happily, but this SAT arm, which I can't, is just as pleasant to contemplate.

It's been pointed out to me that when I run into something I like and can't afford, I can be jealous, or I can realize once again what elegance the human mind can create. Thanks for this review, Mr. Fremer, with your characteristic attention to detail and your gift for addressing key issues. I imagine we are both saving all the nickels we can.

Great review: Thank you for the thoughtful article and for sharing this. Unfortunately, one of your readers is no stranger to the embraces of various barnyard animals (I am avoiding using his name, which means "Tab_A_Slot_B_error"). That reader seems to have developed a personality short circuit. It is possible to make a remote diagnosis, but it would not be fit for print.

"Marc Gomez has chosen null points of 80 and 126mm instead of the more commonly used 66 and 121mm."

My immediate thought was: WHY did he chose these total departing null points?

There should have been some explanations about it.

If this tonearm sounds so much better, could it also have to do with this new geometry?

Then it would be interesting to test this unusual geometry approach at other tonearms -where possible- on an audible improvement too...

I guess the trolling from you-know-who has finally come to an end. That was both hilarious and annoying at the same time. It was also fun to see Mikey and some other people pick him apart.