| Columns Retired Columns & Blogs |

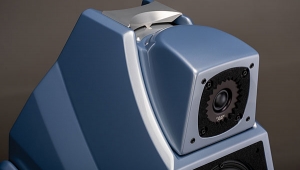

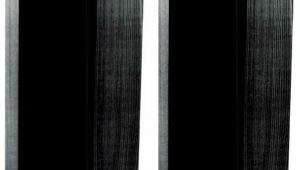

Monitor Audio Studio 50 loudspeaker Heavy Metal

Sidebar 3: Heavy Metal

While discussion continues on the pros and cons of metal-cone drivers, the number of designers using them does seem to be on the increase, including several from the US (Platinum, NEAR, Thiel, Hartke). In addition to Monitor Audio, there's the pioneer of the craft in the UK, namely Acoustic Energy, as well as JPW, Studio Power, B&W, (the Nautilus), and Musical Technology. In Norway, the popular driver maker SEAS is producing a range of aluminium-and-magnesium-alloy units, while the metal-dome tweeter is currently used in many speakers and is produced by a number of manufacturers worldwide.

Fundamentally, the argument for metal rests on its very high stiffness, with the potential avoidance of any unwanted resonance or "breakup" in the intended working range. To optimize metal-cone stiffness, special alloys are used. They're physically hardened and then reinforced by electrolytic anodizing, resulting in a thick coating of a very tough "ceramic," aluminium oxide, on the outside. This anodized surface lends itself to dye coloring, as in the case of Monitor Audio's well known "Gold" dome. Both bass midrange cones and tweeter domes benefit from the chemical reinforcement process.

When commonly used softer materials give or bend, and they generally do so in their operating range, their resonances must be carefully apportioned and controlled to try and attain the highest sound quality. Resonances do color the sound, and their presence is often seen as irregularities in the frequency response. How these errors appear in the measured response may not always be a good indication as to how they actually sound.

With softer, damped materials—fibrous paper or pulp card, plastic and bonded matrix combinations—bending may be imperfect, because these materials don't act as perfect springs. A linear spring recovers immediately from deflection or deformation with near 100% restitution after being stressed. In contrast, many composites and plastics show some memory effect, a slower recovery after bending, and some nonlinear compression with higher forces. This may cause a change in sound quality as sound level is increased. The nonlinear response to high bending forces, and the slowed recovery after bending—technically speaking it is a form of hysteresis—is a factor in the overall linearity of the driver. In return for the favorable internal damping from a resonance viewpoint, non–metal-cone technology can provide a smooth response, nicely extended to the required upper limit, and then may often deliver a smooth acoustic rolloff beyond this point.

In contrast, the metal diaphragm or cone may be essentially perfect from its bass resonance to beyond the required range, and have no resonance whatever in this lower operating region. Potentially, it has a singular freedom from compression and hysteresis distortion. Subjectively that manifests itself, if the overall system design is of sufficient quality, as a great neutrality, a sound with expressive dynamics and a high dynamic range. Clarity can be very high and low-level detail excellently resolved; fine transparency is typical of the genre.

However, there's a price to pay. Like for like, metal is generally heavier than the alternative cone materials, and magnet for magnet, this determines a reduced sensitivity, often a loss of 2–3dB. Metal cones are substantially more expensive than pulp or plastic equivalents, and there's a also higher reject rate in their production.

Finally, while there are no resonances in the primary frequency range, when the metal cone does finally give up and resonate, it lets go with greater exuberance than the alternatives.

So severe is the first resonance, it can rise 10–15dB above the main response with sufficient energy to suck power out of the adjoining frequency bands. Thus a 6½" cone might resonate at 6kHz, desirably higher than the 1kHz typical of a good pulp or plastic cone, but it does so with such amplitude that the cone output decays prematurely into a pre-resonant suckout, tailing off above 2kHz. This makes the crossover design more awkward.

If the crossover rolloff isn't sufficiently fast, some of that 6kHz peak may pop up into the treble band, roughening both the tweeter's sound and its measured response. Some designers resort to anti-resonant traps, electrical filters that seek to notch out the resonance and remove it from the system's sound.

Ultimately it's up to the loudspeaker designer to make the best choices in the system build, regardless of the cone technology employed. Fine speaker systems have been produced using every conceivable combination of driver technology.—Martin Colloms

- Log in or register to post comments