| Columns Retired Columns & Blogs |

London (Decca) Jubilee/Reference phono cartridge

London phono cartridges still carry the famous Decca name (even if only in parentheses), but they are now produced by John Wright, a precision engineer and ex-Decca employee. Wright (not to be confused with his IMF and more recent TDL loudspeaker-designer namesake) was assigned the rights in 1989 by Decca's Special Products division (footnote 1), when the company's new owner, Racal, decided that they didn't want to be involved in the manufacture of audio equipment. Wright worked for 20 years in Decca's phono-cartridge division, where he gained a wealth of experience. As well as manufacturing the current range of London cartridges, he is also responsible for servicing and overhauling older Decca models.

London phono cartridges still carry the famous Decca name (even if only in parentheses), but they are now produced by John Wright, a precision engineer and ex-Decca employee. Wright (not to be confused with his IMF and more recent TDL loudspeaker-designer namesake) was assigned the rights in 1989 by Decca's Special Products division (footnote 1), when the company's new owner, Racal, decided that they didn't want to be involved in the manufacture of audio equipment. Wright worked for 20 years in Decca's phono-cartridge division, where he gained a wealth of experience. As well as manufacturing the current range of London cartridges, he is also responsible for servicing and overhauling older Decca models.

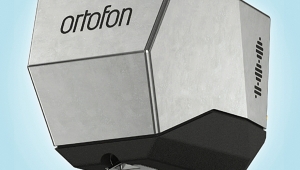

The new Jubilee, so-called in celebration of the 25 years that have passed since the first Decca London cartridge saw the light of day, is built using a milled aluminum-alloy casing whose solidity is reminiscent of the classic Decca pickups of the 1960s, such as the 4RC and the SC4E. The Jubilee is priced at $1600—in typical fine-quality moving-coil territory. For comparison, a (Decca) Super Gold—with the traditional lightweight, sheet Mu-metal, London-type body and fitted with a line-contact van den Hul stylus—costs $650.

Positively coupled

Decca phono cartridges excite wide divergences of opinion among critics. Their contrary natures require unusual care to be taken in system installation and the choice of ancillary equipment, but many audiophiles adore them and will accept no substitute. Some try them out, admire certain aspects of the sound, but fail to reach an acceptable system balance; others fail to get anywhere at all, and wonder what all the fuss is about!

Decca's "Positive Scanning" technology is responsible for what I described some 18 years ago as "both the glimpses of heaven and the occasional taste of hell." (This was in a review of the original Decca London Blue and Gold cartridges. These top-ranking models then retailed for around the $100 mark! How times have changed.)

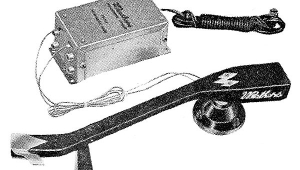

In part, the operating principle is closely related to the variable-reluctance design developed by GE from earlier 78rpm versions in the mid-1950s for monophonic LP playback. I first used one of these designs fitted to a massive Garrard auto changer. The cantilever was made of magnetically permeable alloy, fixed at one end, with the motion of the stylus end sensed directly by two magnetic pole-pieces. Coils wound on these pole-pieces produced the transduced electrical output.

The principle of directly sensing the stylus motion is an attractive one. It avoids the problems that occur with the usual remote-generator systems, which either move coils between the poles of a magnet or move a small induced magnet in front of fixed coils. In either case, the stylus tip motion is transferred to the generator or motor by the cantilever—a lightweight rod or tube.

The cantilever's "lever" is important, as it allows a relatively heavy and efficient electrical generator to be used while ensuring a low overall moving mass as seen at the stylus tip (footnote 2). (Low moving tip mass is directly associated with good trackability, particularly at high frequencies.) Of necessity, the lever must have a pivot point or bearing, and it is here that losses may occur between the tip and the generator. Subjective terms such as "cantilever haze" and "poor generator precision" are often used to describe the sound from such non–direct-coupled designs, equating to losses in clarity, dynamics, and channel separation.

Various direct-coupled moving-coil cartridges have been produced, a current example being the Ikeda Kiwame reviewed by Dick Olsher in February 1993 (Vol.16 No.2, p.164). Several difficulties arise with these units, not the least being the need to attach four lead-out wires to the coil assembly. These wires must all be sufficiently flexible not to interfere with the stylus motion.

The 1950s GE cartridge was required to trace and sense lateral (dual-mono) modulation only. To detect signals recorded in 45/45 stereo (footnote 3). Decca both had to provide some compliance in the vertical direction and add a second magnetic sensor to translate vertical motion into an electrical signal proportional to the difference between the two stereo channels. The lateral and vertical signals, representing the sum (L+R) and difference (L–R) information, respectively, allow the independent left- and right-channel output signals to be extracted. (Neglecting phase and summing the vertical and lateral signals gives L+R+L–R = 2L. Subtracting the vertical signal from the lateral signal gives L+R–L–(–R) = 2R.)

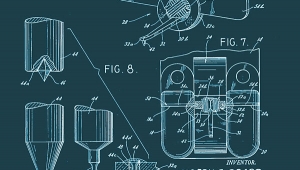

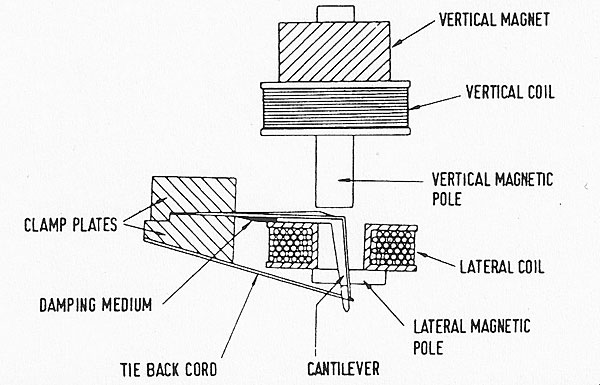

In the Decca stereo pickup design, the moving element, called the "armature," is a two-axis device with a complex form, folded almost to a right angle (fig.A). Decca dubbed the pickup's direct-coupling aspect "Positive Scanning": the vertical motion of the stylus is sensed directly by the vertical pole; similarly, lateral motion is read by the proximate lateral pole. (In this detail, the Decca is similar to the GE system.)

Fig.A The Decca "Positive Scanning" vertical/lateral sensor.

The armature is formed with a press tool from foil sheet just a few microns thick. Tempering in liquid nitrogen stabilizes the mechanical properties of the flexible armature. While its shape ensures rigidity in both required planes—this essential to control resonances in the audible range—ultimately the armature must also flex at the pivot formed at the clamping point. The armature is held—rather improbably in its correctly aligned, pretensioned state—by a short tieback thread or cord visible beneath the cartridge. The armature is also in contact with a thin block of damping medium near the clamp.

Jubilation

Specific technical improvements for the Jubilee include the use of high-flux samarium/cobalt magnets to allow increased clearances between the stylus tip and the carriage body, reducing the tendency for the latter to foul warped discs.

The Decca's high output has been maintained at 1mV/cm/s (typically 5mV for 5cm/s lateral modulation), so no step-ups are required. The generator coils are of quite low inductance, and are relatively unaffected by loading compared to conventional moving-magnet designs. A parallel capacitance of 150–800pF, coupled with a shunt resistance of between 25k and 47k ohms, is optimum. (32k ohms is often suggested.)

Footnote 1: Once a division of the Decca Record Company (of Decca, Deram, London, ffrr, ffss, and not-signing-the-Beatles fame), the Special Products Division became an orphan when the record label was absorbed by PolyGram in the late 1970s.—John Atkinson

Footnote 2: A severe conflict arises between the need to generate sufficient electrical output and the need to keep the mass of the coil assembly as low as possible. (Together with the stylus, this should ideally be less than a thousandth of a gram!)—Martin Colloms

Footnote 3: So-called because each groove wall is at an angle of 45° to the vertical. The modulation for each stereo channel is therefore orthogonal—at 90°—to the other, thus maximizing channel separation. The sum of the two channels' information (L+R) is represented by lateral stylus motion; the difference between the channels (L–R) is represented by vertical motion.—John Atkinson

- Log in or register to post comments