| Columns Retired Columns & Blogs |

Cutting Up: Stereophile's Liszt Piano Sonata LP Page 2

Cutting at Camarillo: Wes Phillips

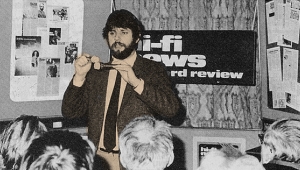

John Atkinson and I flew to Camarillo in November 1996 to test a pet theory: Given the audible superiority of the 20-bit data coming off the Nagra-D to the 16-bit CD standard, would an LP cut from the 20-bit digital master tape preserve enough of that quality to justify pressing a vinyl disc? Our partners in this project were RTI's Don MacInnis and Analogue Productions' Chad Kassem, who had recently purchased David Wilson's disc-cutting facility and had installed it within RTI as AcousTech (footnote 1), under the direction of legendary mastering engineer Stan Ricker. Stan's done it all: an accomplished double bass player, he's also run record presses for Keysor, mastered the original Mobile Fidelity half-speed-mastered LPs at the now defunct JVC Cutting Center in Los Angeles, engineered some of the earliest digital recordings for Delos and (with Keith Johnson) the legendary 1987 Moscow Sessions CDs for Sheffield Lab, and won countless Grammys.)

Footnote 1: This mare's nest of corporate identities may be confusing. RTI is the foremost independent record pressing and plating facility currently producing high-quality LPs. Analogue Productions reissues high-quality LPs and CDs, which are marketed by Acoustic Sounds, and is therefore a big RTI customer. Together, they purchased Wilson's cutting lathe and set it up independently as AcousTech—see Michael Fremer's "Analog Corner" column, Stereophile November '96, Vol.19 No.11, p.57.

John Atkinson and I flew to Camarillo in November 1996 to test a pet theory: Given the audible superiority of the 20-bit data coming off the Nagra-D to the 16-bit CD standard, would an LP cut from the 20-bit digital master tape preserve enough of that quality to justify pressing a vinyl disc? Our partners in this project were RTI's Don MacInnis and Analogue Productions' Chad Kassem, who had recently purchased David Wilson's disc-cutting facility and had installed it within RTI as AcousTech (footnote 1), under the direction of legendary mastering engineer Stan Ricker. Stan's done it all: an accomplished double bass player, he's also run record presses for Keysor, mastered the original Mobile Fidelity half-speed-mastered LPs at the now defunct JVC Cutting Center in Los Angeles, engineered some of the earliest digital recordings for Delos and (with Keith Johnson) the legendary 1987 Moscow Sessions CDs for Sheffield Lab, and won countless Grammys.)

At AcousTech, stuffed into what used to be a high-speed tape-duplicating room, was the Neumann VMS 70 cutting lathe (fitted with a Neumann SX 74 cutter head) and control desk, a Studer tape deck, a pair of WATT/Puppies that looked mighty like the Ur-pair, and an extra table shoehorned in to support Stereophile's gear. We promptly set up the Mark Levinson No.30.5 on the table and used the Studer as a stand for the mighty Nagra, in order to have it close to Stan's console. The Nagra fed the Levinson processor via the Meridian 518 (this time used solely as a jitter-reduction box) and two lengths of Madrigal AES/EBU cable. The Levinson in turn was connected to Stan's console with MIT balanced cable. After the requisite fumbling for the right wires, we had everything connected. JA played back the 1kHz -20dBFS reference tone from the Nagra tape and we promptly ran into our first problem of the day.

At AcousTech, stuffed into what used to be a high-speed tape-duplicating room, was the Neumann VMS 70 cutting lathe (fitted with a Neumann SX 74 cutter head) and control desk, a Studer tape deck, a pair of WATT/Puppies that looked mighty like the Ur-pair, and an extra table shoehorned in to support Stereophile's gear. We promptly set up the Mark Levinson No.30.5 on the table and used the Studer as a stand for the mighty Nagra, in order to have it close to Stan's console. The Nagra fed the Levinson processor via the Meridian 518 (this time used solely as a jitter-reduction box) and two lengths of Madrigal AES/EBU cable. The Levinson in turn was connected to Stan's console with MIT balanced cable. After the requisite fumbling for the right wires, we had everything connected. JA played back the 1kHz -20dBFS reference tone from the Nagra tape and we promptly ran into our first problem of the day.

"Where's the gain?" asked Stan.

"What do you mean?"

"If I bypass the board—which I'd really like to do, since it's got about a mile of wiring in it—I come up 6dB short of the lowest level I'd feel comfortable cutting at. I could even use another 8dB or so to feel really good about it."

"The No.30.5 puts out the CD reference level of 2V RMS," John reassured Stan.

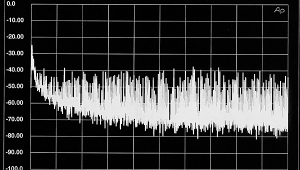

"That may be. But my concern is that the quiet passages will put the pressing at a disadvantage. The average level will be -20 or -30dB, while the noise level of an LP is usually about -50dB. That's not much of a spread."

Even using the board's active stages, we could only boost the input to Stan's minimum requirements, and he clearly wasn't happy about that course. We discussed our options and rethought the chain for a while. Finally, Stan suggested we use a Mackie 1202, a small mixing board that had been used for tape-duping. "Real audiophiles might be too snooty to use this," Stan declared, "but it's real clean. I'm amazed by how good it sounds."

This entailed yet another search for cables, this time terminated with ring-tip-sleeve phone jacks. "Oh yeah! Now I've got gain out the ass!" Stan burbled happily.

Time for a reference cut. As Stan opened a box of lacquer blanks, John—remembering all the furor over lacquer quality that accompanied the rise of CD—asked what Stan thought of the current crop of lacquers. "I really like these Apollo lacquers, but the Transcos aren't worth doodley-squat! The Apollos are as good as any I've ever cut.

"I'm ready for this session. I even put a new cutting stylus in the head this morning." We ran into problems with the first lacquer, however. Stan: "I've dropped a chip! First time that's ever happened here." When grooves are cut into a lacquer blank, the material carved out of the lacquer is lifted in a single continuous "curl" that must be sucked out of the way by the cutting lathe's vacuum system, or it will mar the lacquer's surface. The "chip" was that curl of lacquer, "dropped" by the vacuum system.

Footnote 1: This mare's nest of corporate identities may be confusing. RTI is the foremost independent record pressing and plating facility currently producing high-quality LPs. Analogue Productions reissues high-quality LPs and CDs, which are marketed by Acoustic Sounds, and is therefore a big RTI customer. Together, they purchased Wilson's cutting lathe and set it up independently as AcousTech—see Michael Fremer's "Analog Corner" column, Stereophile November '96, Vol.19 No.11, p.57.

- Log in or register to post comments