| Columns Retired Columns & Blogs |

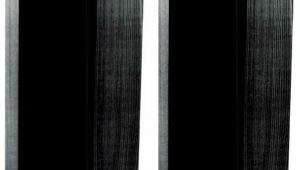

It's funny how you first see something from a distance and your couriosity takes over for you to move closer. It was the first time i had seen the 801's. I was aware of the 800 and the 802 but i was drooling at the 801. I love bass and seeing that large woofer in that magnificent cabinet made me forget, for a moment, about the 800 and the 802. Their large brother had me hypnotize. I was told about 2 years ago that B&W no longer produces the 801. I'm crying.................