| Columns Retired Columns & Blogs |

Bryston BCD-1 CD player

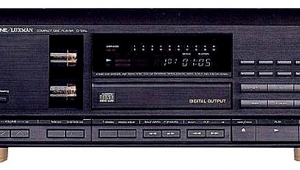

Bryston's first CD player, the $2695 BCD-1, is a drawer-loading player with a front panel of polished aluminum. The slim disc drawer, engraved with the Bryston logo, sits in the panel's center. To the drawer's left are an infrared sensor and Open/Close button, then a two-line, 16-character alphanumeric display. To the drawer's right are the usual transport controls and a power On/Off button. All of these functions are also accessible via the BCD-1's remote control, as well as two more: Back and Forward. Hold down either and the player moves through the selected track at several times normal speed until the button is released.

The rear panel has sets of balanced and unbalanced right and left analog output jacks, the XLRs wired with pin 2 positive. There are three transformer-coupled digital output jacks—S/PDIF via an unbalanced, gold-plated RCA and TosLink optical, and AES/EBU via an XLR—but no digital input jacks. An RS-232 port allows the BCD-1's firmware to be updated, and a 2-pin trigger socket mates with a CO11COA-11102 bare-wire terminal block connector (supplied) to remotely power-on the BCD-1 when an external 2-12VDC trigger signal is applied.

Removing the BCD-1's top panel revealed excellent build quality: minimal point-to-point wiring, high-quality 0.1%-tolerance metal-film resistors and polystyrene capacitors, and all components neatly laid out. Soldered and other gas-tight mechanical connections are used for the signal circuits. The thick, high-quality circuit boards are of double-sided epoxy-glass, with clearly printed component designators. Bryston hand-selects and -matches the BCD-1's transistors to minimize noise and distortion.

Centered behind the BCD-1's front panel is its Philips L1210 disc transport. The drive clock and control circuitry sit to the right of the transport, under a metal shield. A full-depth, multilayered PCB just behind the rear panel carries the D/A and analog stages. To the transport's left are the linear power supplies for the digital and analog circuits, with their reservoir electrolytic capacitors and heatsunk voltage regulators, next to a large toroidal power transformer. A small RC network filters out radio-frequency interference (RFI) on the AC power supply.

The BCD-1's full-function remote control is made of highly attractive brushed aluminum. It controls everything associated with the CD player—Mute, Track, Open/Close, Power Off/On, and discrete code entry—and it's backlit for use in the dark. As with other Bryston remotes, this last feature is triggered by a motion detector: the remote illuminates when you pick it up.

I experienced one operational surprise with the BCD-1. Occasionally, when I pressed the Open button on the front panel, the tray motor did not respond for five seconds. I also found it strange that, instead of the usual power-on LED, the BCD-1 has a red Standby light that goes dark when the player is powered on. Otherwise, the BCD-1 functioned flawlessly while I had it in my system; CDs placed in its tray loaded quickly and played without delay.

Design considerations

One of Bryston's primary design goals for the BCD-1 was to reduce jitter (ie, mistimings of the digital signal presented to the DAC). Bryston replaces the oscillator in the Philips transport's servo circuit with one of its own design, and hand-matches the new oscillator to the drive. The L1210 drive was chosen for its quiet operation and reliability. Bryston rejected other OEM drives because they were actually DVD transports with multiple-frequency clocking circuits, whereas the Philips had been optimized for "Red Book" CD playback, operating at multiples of 44.1kHz.

The signal recovered from the transport is fed to a Crystal CS4398 chip, described as a hybrid, 128x-oversampling 24-bit delta-sigma DAC. The original 44.1kHz data are upsampled to create a new 192kHz sampling frequency. While this process adds no new data to the signal, it shifts noise from the audible spectrum up to ultrasonic frequencies. This allows the DAC chip's digital filter to eliminate noise well above the audible range before converting the data to analog and low-pass filtering it a second time.

In addition to the low-jitter common master clock, the Bryston engineers have done two other things to reduce noise, jitter, and distortion before the D/A conversion stage. Careful routing of the circuit-board traces reduces noise from capacitive coupling between the digital- and analog-bearing lines; and discrete digital and analog power supplies, closely regulated and filtered, help maintain the integrity of the audio signal.

- Log in or register to post comments