| Columns Retired Columns & Blogs |

Stop Digital Madness!

The title of this month's column is the legend Sheffield Labs emblazoned on a T-shirt a couple of years ago, to promote their jaundiced view of digital audio. Since then, even Sheffield's reactionary perfectionists softpedalled their anti-digital crusade, perhaps because of the number of CDs they've been selling! Their personnel no longer wear those T-shirts at CES, which is unfortunate. Although most people in the audio field no longer see digital audio as madness, digital denouncing is still very much with us.

I refer to the recently-announced discovery, by a Professor Judith Reilly, that digitally mastered analog discs damage turntables. Now, reilly...!

Prof. Reilly, who teaches physics and mathematics at Quinsigamond Community College in Worcester, Mass., has uncovered what appears to be a statistical correlation between the number of hours a phono turntable has been used to play digitally mastered discs, and the constancy of its speed.

This seemingly outrageous story was published in the March/April 1985 issue of Fanfare magazine, in Neil Levenson's regular column. If memory serves me, Neil was also one of the first writers to report that digital audio rots the innards of amplifiers. (Obviously, all those spiky digital Ones abrade the insides of the wires!)

According to Levenson's report, Professor Reilly, a vocal-music enthusiast, observed that her own turntable exhibited an unusual amount of speed variation, and confirmed with a tachometer that, indeed, it was no longer meeting its speed-constancy spec. For reasons not explained in the article, Prof. Reilly began investigating the possibility that her turntable had been damaged by playing digitally mastered discs, and set out to form a hypothesis.

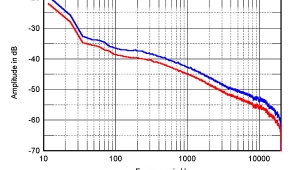

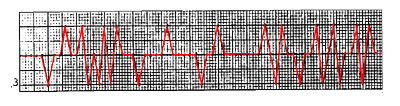

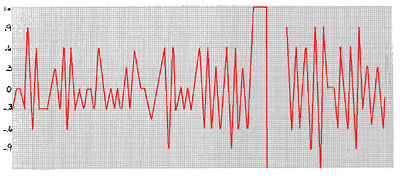

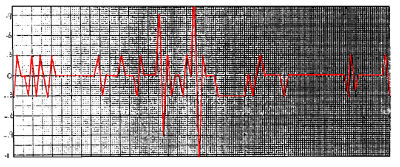

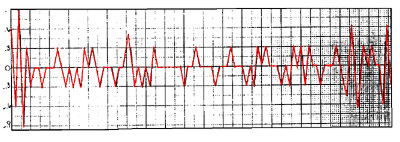

Over a period of time, she measured the speed constancy of "many hundred" high-quality turntables, mostly in dealer showrooms, obtaining a "history" of each turntable to determine how often it had been used to play digitally mastered discs. The results were unequivocal: every measurement showed that a turntable's speed regulation deteriorated after a few hours of playing digitally mastered discs; if the playing extended for more than a few hours (say, 10), the damage was irreversible (the speed constancy variation was permanent), regardless of the type of disc played (fig.1). If, however, the playing was for just a few hours, the speed variation might go away, at least most of it (fig.2). Interestingly, Prof. Reilly found that the speed variation in "damaged" turntables was temperature-related: at temperatures below 65 degrees F. little or no speed variation was noted, but at higher temperatures it became great (figs.3 & 4).

Fig.1 Typical "non-digitized" turntable, a new, never-played Goldmund Studio (after Reilly).Fig. 1

Fig.2 Goldmund Studio playing Telarc digitally mastered LP: after 4 minutes (left), after 9 minutes (right) (after Reilly).

Fig.3 Goldmund Studio playing SHeffield Labs LP, 5 minutes after test in fig.2 (after Reilly).

Fig.4 Benefit of air-conditioning: "thoroughly digitized" Beogram 1800, but air-conditioned (after Reilly).

Now, it is one thing for an accredited scientist to report such an apparently preposterous phenomenon; it is another entirely to explain it in scientific terms. Undaunted, Professor Reilly takes a crack at it. Here is her scenario:

• Observation: Permanent damage is done to turntables by playing of digitally mastered records.

• The only observable difference between analog and digital records is large amusical spikes (see scope photos) of much greater magnitude than the music content in which they occur.

• The damage must be done by these pulses.

• Since the damage is permanent, it must involve some sort of structural modification to the turntable.

• This "modification" consists of microscopic cracks induced into the turntable's bearing and spindle by the "digital" spikes.

• The platter speed variations in damaged 'tables occur in cyclic bursts, which could be due to periodic changes in bearing friction.

• Such changes could be caused by changes in temperature between the bearing surfaces.

• If the microcracks exist, and if they serve as a focus for friction-generated heat buildup, then the concentration and release of this energy is the mechanism causing the speed variations measured.

- Log in or register to post comments