| Columns Retired Columns & Blogs |

Soundsmith Strain Gauge SG-200 phono cartridge system Page 2

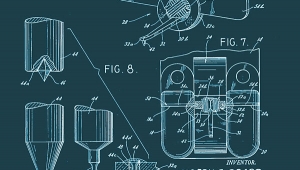

Magnet-based cartridges, MM or MC, are devices that are sensitive to velocity, which is measured as distance over time; their electrical output is directly proportional to the stylus's speed as it's moved back and forth by the zigs and zags in the groove. By contrast, strain-gauge and piezo-electric (crystal or ceramic) cartridges are sensitive to displacement, without regard to time. Move the stylus in such a system the same distance, whether very slowly or very quickly, and the electrical output will be the same.

Magnet-based cartridges are very sensitive to how quickly or slowly the generator system moves. Moving such a system slowly produces far less output than moving it quickly. Think of your bicycle's generator: the faster you pedal, the brighter the headlight. So imagine an LP cut "flat," with no equalization applied, and using a magnetic cutter head—another velocity-sensitive device. Lower frequencies would move the cutting stylus far more than higher frequencies, which would create serious problems when the record was played by a displacement-sensitive strain-gauge cartridge. However, RIAA equalization is applied, greatly cutting LF and slightly boosting HF lateral displacement.

So consider a 20Hz–20kHz test-record signal that's been recorded at the same amplitude for all frequencies, but using RIAA. Since we've boosted the lateral displacement of the highs and cut the lateral displacement of the lows, we get nearly equal groove displacement at all frequencies. Thus, a displacement-sensitive device like a strain-gauge cartridge creates an automatically flat response with no RIAA equalization applied to the output. Instead of a complex filter network in the line, all that's needed is a simple, low-distortion preamplifier stage.

In sum, a strain-gauge cartridge is a low-mass, low-inertia mechanical system that can accurately trace a groove with blazing speed and requires no RIAA equalization—vs a higher-mass, higher-inertia system that can't track or trace as quickly, and that requires a complex RIAA equalization circuit.

In reality, there are subtle changes in equalization in the RIAA curve that need to be compensated for, and Soundsmith's preamplifier does that—but it's still much simpler than a full-blown RIAA circuit, and the resulting frequency range is claimed to be an astonishing DC–70kHz (though the circuit also includes a staggered low filter for minimal impact on the signal)

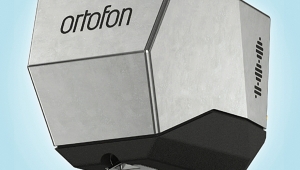

Soundsmith Strain Gauge SG-200

Its two bright-blue tubular LEDs, which run vertically through the metal body's horizontal slats, give the Soundsmith Strain Gauge cartridge a unique look. Unlike most cartridges, it features controls for adjusting vertical tracking angle (VTA) by ±3°, as well as azimuth, though these are to be used only if your tonearm doesn't offer them.

The cartridge's mass (10gm) and compliance are suitable for any modern-day tonearm of medium to high mass. The compliance is unique in being designed to vary more with vertical tracking force (VTF) than is usual: from 16µm/millinewtons at 1.5gm to 10µm/mN at 2.5gm. This allows for a bit of "tuning," according to Peter Ledermann, but even within that range, it's a low- to medium-compliance design.

When you order your Strain Gauge cartridge, it comes standard with the SGS-5 nude line contact/Ruby cantilever and power supply for $5499.95. However, Ledermann says that most buyers opt for the SGS-6, an "Optimized Contour" nude line-contact stylus with a ruby cantilever, which adds $100 to the system price.

Soundsmith offers six user-replaceable styli:

SGS-1: bonded Shibata, aluminum cantilever ($149.95)

SGS-2: nude elliptical, aluminum cantilever ($199.95)

SGS-3: 1-mil radius, conical, aluminum cantilever ($199.95)

SGS-4: 3-mil radius, conical, 78rpm, aluminum cantilever ($199.95)

SGS-5: nude line contact, ruby cantilever ($399.95)

SGS-6: nude "Optimized Contour" line contact, ruby cantilever ($499.95)

Soundsmith strongly recommends factory installation of your choice of stylus, to ensure perfect alignment and top performance. Removing and reinstalling the same stylus won't change its performance, but switching to another stylus at home requires resetting azimuth, VTA, and stylus rake angle (SRA), all of which are critical for extracting maximum performance from this system (or from any cartridge, really)—but particularly with the two most severe stylus profiles. When ordering additional or replacement styli, free factory custom fitting is recommended for top performance.

The review sample of the SG-200 Strain Gauge came fitted with the SGS-5 and SGS-6 styli.

Setup and use

Hookup follows the standard system of four color-coded pins, although, as the instructions point out, since the cartridge's strain-gauge elements have no polarity and are purely resistive devices, you can reverse polarity with no change in performance. But why would you?

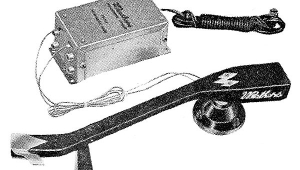

The SG-200 power supply is based on a pair of 24V DC wall warts that I didn't plug in until I'd installed the Strain Gauge cartridge in the Graham Phantom II arm and made all connections. When everything was plugged in, a flip of the power switch lit up green and red LEDs on the interface that indicated that both negative and positive supplies were active.

Leave the Soundsmith preamp's Auto Mute switch in the down position on plug-in, and the cartridge's two blue LEDs light and your excitement rises. If you put the Mute switch in the up position, the yellow Mute LED glows until the preamp senses a signal from the cartridge, at which point the blue Unmute LED will light. This prevents loud pops, should you accidentally drop the stylus onto the record. A second muting system senses a faulty connection between the cartridge and preamp. It also lets you unplug the tonearm or headshell without turning down the volume.

VTA and SRA are critical with both supplied styli, so I used a digital USB microscope to achieve 92° SRA. This put the cartridge's body up in the back (Soundsmith's recommended orientation is parallel to the record surface).

- Log in or register to post comments