| Columns Retired Columns & Blogs |

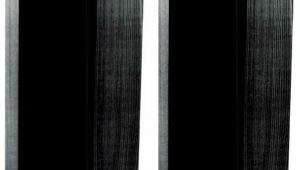

MartinLogan SL3 loudspeaker Trying to Control a Lightning Storm

Sidebar 4: Trying to Control a Lightning Storm

Talking to Gayle Sanders is always a treat; he's enthusiastic and gestures effusively, staying in constant motion until something totally engages his attention. Then, it's as though you can see the intellect click on: His eyes narrow, and he seems to quiver as he brings his full attention to bear. This can cause conversations to move in an odd rhythm, but one adjusts. I recently realized that I had never heard the saga of Martin-Logan's early days. I asked Gayle to tell me how he'd gotten into hi-fi, and why he'd been driven to build electrostatic loudspeakers.

Talking to Gayle Sanders is always a treat; he's enthusiastic and gestures effusively, staying in constant motion until something totally engages his attention. Then, it's as though you can see the intellect click on: His eyes narrow, and he seems to quiver as he brings his full attention to bear. This can cause conversations to move in an odd rhythm, but one adjusts. I recently realized that I had never heard the saga of Martin-Logan's early days. I asked Gayle to tell me how he'd gotten into hi-fi, and why he'd been driven to build electrostatic loudspeakers.

Gayle Sanders: I grew up in a musical family. As a kid, I built my own guitar. I read a bunch of articles, sourced my magnets, built a body, hand-wound my own pickups, cut the neck out of rosewood, fretted it myself—and I had my very own instrument. Not that I posed a big threat to Fender.

I went into architecture because I loved to design, but there was much too much rote work and not enough design. Looking around for something to do, I began working at an audio store as a salesman, and fell in love with the audio industry—it was the perfect place for the musician/technologist. And I was absolutely enchanted by electrostatic technology from the very first time I experienced it.

The Quad ESL gave me a hint of what I was looking for, but I'd have to say that hearing Arnie Nudell's Infinity Servostatics really was a defining moment. I owned a pair, so I also became very familiar with the rather considerable problems confronting electrostats—which is, I'm sure, why Arnie has moved on to other technologies.

Wes Phillips: What were those problems?

Sanders: While the Servostat showed that inefficiency and dynamic-range limitations could be transcended, the mechanics were still hard to resolve: keeping the diaphragm correctly tensioned, keeping the conductive coatings bonded to the diaphragm, preventing the diaphragm from arcing under dynamic excursions—these were all extremely problematic.

At about that time I suffered audio burnout and left the industry. I moved to Lawrence, Kansas, where I ended up working for Rueuter Organ Company—a firm that builds tracker organs from the ground up. I would take the ranks of pipes and the wind-chests and the consoles, and I would engineer the organ into a specific room. I just loved it—it was a thrilling experience every time out. But I like building things, so the whole time I worked for Rueuter, I was moonlighting—assembling systems for friends and for discos, constructing record racks, and stuff like that.

I met John Kiefer, a local record mogul, and we started a hi-fi shop. We were immediately successful, but I discovered that retail wasn't my thing. By 1978 I realized that I wanted to build stuff. Kansas University had a great engineering library, so I spent a year and a half in the stacks investigating everything ever written on the subject of electrostatic speakers.

Phillips: Some of that information must have gone practically back to Edison.

Sanders: Absolutely! Kellog and Rice did their work in the '20s, which was the great flowering of speaker design—electrostats, ribbons, and moving-coil speakers all come out of that era. Kellog and Rice lacked really good insulation technology—and, my God! their diaphragm material was a pig's intestine burnished with gold leaf! Even so, the difference in clarity and response was immediately apparent. It was a delightfully accurate and enchanting technology—theoretically, you could design a low-mass, extremely linear, crossoverless diaphragm that was capable of handling up to nine octaves of information—but it had huge drawbacks in implementation. The materials were not available, and the technology didn't really mature because of all the focus that had been placed on dynamic speaker design.

When you design an electrostat, you're trying to control a lightning storm. Electrostats didn't get loud, they blew up amplifiers, they blew up themselves—but these were not immutable issues, these were physical issues. I never felt that the concept was flawed. I pursued electrostatic technology believing that finding the right materials would solve the "insurmountable" problems that had plagued it.

Peter Walker, Jim Strickland, Arnie Nudell, and Arthur Janszen had all done significant work, but I still felt the transducer element could be taken much further. I took to calling high-technology firms and asking questions and, surprisingly, I found a lot of engineers who got excited by my project and contributed information that led to several of Martin-Logan's breakthroughs, including vapor-deposited coating of the diaphragm and conformal coating of the stator material. That's also how we got the highly insulated spars we use as spacing elements on our transducer.

- Log in or register to post comments