| Columns Retired Columns & Blogs |

Listening #65 Page 2

First, some encouraging words for the budget-minded hobbyist or the DIY audiophile of any means: The Thorens TD 124 Mk.II that I purchased last year for about $700 (including a TP-14 tonearm that isn't quite usable) required only $120 in parts to achieve mere functionality—all manufactured in Switzerland by Schopper A.G. and sold in the US by Audioarts. And of the improvements I've put in place since that time, the most effective by far was the cheapest.

The things my turntable required to get up and running were a new drive belt ($35), new rubber "mushrooms" for isolating the player from its plinth ($60/set of four), and a fresh bottle of Thorens oil ($25) for the main bearing, idler wheel bearing, intermediate pulley bearing, and other sundries. I was then and still am utterly astounded that the idler wheel itself did not need to be replaced—but literally every Thorens expert with whom I've spoken says that the need for such a thing is exceedingly rare, occasioned only by contamination with oil or grease, or the sort of flat spot that results from having left the drive mechanism engaged for more than, say, a decade.

But the single most effective improvement in my turntable's performance—the one that every single Thorens TD 124 owner should put in place right now—came about when I replaced the rubber grommets that isolate the motor from its surroundings ($50/set of six, the number required for any Mk.II TD 124, or to easily bring an original TD 124 up to Mk.II performance levels). I dolefully admit that I had a fresh set of those gummimuffens sitting here for months, but installed them only recently because I didn't think they'd make that big a difference.

That was because the gummimuffens on my 124 Mk.II looked fine: They weren't in the least dried out or cracked—which is more than I can say for my player's original suspension mushrooms, which were useless (or, as John Wilkes Booth might have said, "useless, useless"). Yet when I replaced those original gummimuffens, my player had a much lower noise floor, with cleaner, deeper bass notes, and less grain and artificial texture (things I hadn't really known were there to begin with), and there was a clearly audible improvement in the 124's sense of melody, flow, and overall musical naturalness.

The job itself was easy: Working from above, I simply removed three C-clips and their fiber washers from the motor retaining shafts, pried away the old grommets, and slipped the new ones into place, using a denuded Q-Tip to properly seat their molded-in grooves on the edges of the holes made for them. Other, more expensive upgrades have further improved my Thorens, but none has been of the same degree as those six little grommets. None.

Before all that, of course, I had to remove the TD 124's platter—which is more or less where we came in. That procedure is tricky because the conscientious TD 124 owner should never, ever lift the iron platter and main bearing shaft away from the stationary bearing well: The well lacks the sort of air vents common on other such bearings, and to casually reinsert the platter and spindle would risk damaging the seal between the Thorens's very precisely machined bearing well and its removable thrust plate. (The only safe way to reassemble a 124's bearing is to loosen the three small bolts that hold the bottom plate in place, allowing air to escape, and to gently replace the spindle—after which the bottom-plate bolts can be retightened.) Before replacing gummimuffens, belts, or virtually anything else, one must remove the three bolts that hold the platter to the bearing-spindle flange and lift it carefully away—slightly more difficult than it sounds, as the platter is quite heavy, and must be lifted with sufficiently even force that the platter comes straight up and away from the spindle. (Allowing a tiny amount of WD-40 to seep between the platter and the record spindle—which is, in fact, the very top part of the bearing spindle—will help, as will polishing that top spindle the next time your turntable requires disassembly.)

The second biggest improvement to my 124's performance came courtesy of Schopper's platter-bearing rebuild kit ($90), complete with new gasket, thrust plate, and bolts. That kit also came with a new thrust plate for the intermediate pulley bearing, which is accessible from underneath the turntable chassis. That, too, got my attention: Many Q-Tips were soiled in its cleaning, and its oil is now fresh as a daisy. And while I had the chassis upside down, I cleaned the speed-adjustment mechanism's thin metal band with a rag dipped in WD-40, and cleaned and lubricated the pivot points for the lightly sprung brass hinge that allows the idler wheel to go in and out of contact with the platter rim. Doing that, then adding a drop of Thorens oil to that mechanism's main pivot (from above), made an enormous difference in my TD 124's ability to accelerate from a standing start.

Acceleration—and speed stability—were also improved when I tackled the seemingly daunting task of cleaning and re-lubricating the motor itself. But it wasn't really so hard at all, and I'll bet you're up to it, too. Do it with the motor casing still fastened to the turntable: The drive pulley, which is held to the motor's armature shaft with two setscrews, must be removed from above, and the motor cover must be removed from below. Thanks to Joachim Bung's excellent book Swiss Precision, which I reviewed in April, I knew that that bottom cover contained the lower bearing and thrust ball, so I was careful not to lose the latter. From there it was a simple matter of removing the armature, cleaning its shaft and the upper and lower bearings with several more swabs, soaking the porous bronze bearings with oil, waiting, adding more oil, and carefully realigning the lower bearing during reassembly. The motor, an obviously durable and well-made thing, responded happily, and appeared anxious for its next 46 years of vinyl-driving.

No overheating . . .

Reconditioning that motor left me with a wonderful feeling of accomplishment—yet as well as I did, and as solidly as my player now performs, there are Thorens experts who can take the TD 124 even further.

Chief among them, of course, is the estimable Juerg Schopper. Since 1923, Juerg's family has operated a musical-instrument store in northern Switzerland, which long ago added records, record players, and tape recorders to their line of merchandise. Today the family business exists as Schopper A.G., a high-street shop in Winterthur with an emphasis on new and used LPs and very-high-quality playback gear. Of the latter, Schopper's specialty is the classic Thorens turntable, and their operation has expanded to include the engineering and manufacture of TD 124 replacement parts and upgrades.

Thanks to his friendship with key veterans of the company's plant in St. Croix—most notably the youthful Jacques Basset—Juerg Schopper has been able to pick up where the Thorens engineers left off. Schopper has even begun to produce a decades-old design for an upgraded version of the main platter bearing ($750), something that Thorens S.A. decided long ago would be too expensive for a mass-produced turntable such as theirs. Another advance came when Schopper began his quest to produce new samples of the 124's aluminum upper platter ($590), and discovered a distinctly harder alloy that, he says, makes for a better sound.

Schopper's crowning achievement as a manufacturer may be his replacement for the original magnetically reactive platter. For reasons that probably go beyond its advantage in centrifugal energy, that massive iron platter is considered one of the keys to the 124's excellent musical performance—second only to its combination of a relatively powerful motor and idler-wheel drive—and most Thorens enthusiasts appear to agree that the company's briefly offered and significantly less heavy aluminum-alloy platter doesn't sound nearly as good. But the flaws of the original are well known to owners of Deccas and other phono cartridges with similarly greedy magnets, and Juerg Schopper has offered them the first really viable alternative. For his replacement platter ($1490) he turned to gray (or "gray-cast") iron, a fairly ancient alloy in which most or all of the carbon content exists as flakes of graphite. The resulting metal is almost completely nonmagnetic—and in the hands of the machinists whom Schopper A.G. has commissioned, the resulting platter is a thing of beauty, at least as free from run-out error as the original (itself no slouch).

Yet the greatest achievement of all is one of a more general sort: Drawing on his own experiences, as well as those of his employee Gino Bertolo—who has developed a motor-rebuilding regimen slightly more intense than that with which brain scans are administered—Juerg Schopper has begun to offer full TD 124 rebuilds, the fruits of which are available either as ready-to-ship products, or as a battery of services for current Thorens owners. To help me appreciate this series of accomplishments, Schopper recently sent me a completely refurbished TD 124 to compare with my tidied-up original. The Schopper sample featured Juerg's upgraded bearing, main platter, and upper platter, along with a new beechwood plinth, isolation grommets, armboard, drive belt, platter mat, and, of course, gummimuffens. Its motor had been rebuilt and tested by the good Mr. Bertolo (a service that in and of itself can be had for $590 plus shipping), and its chassis had been refinished in Mercedes silver, with an especially wet-looking clearcoat on top.

Its appearance was ravishing, its sound even more so. The full brace of Schopper refinements created a record player that could compete with virtually anything I've heard in terms of treble openness and clarity, midrange detail, and—especially—bass extension, yet which preserved and enhanced the 124's well-established strengths: its relentless sense of musical flow and momentum, the size and solidity of the images it creates, and its ability to startle and engage the listener with its dramatic and decidedly nonwimpy sound. It simply must be heard by anyone who wants the ultimate in domestic music playback.

You could look at it another way and say that the all-out Schopper treatment makes a musically successful product a bit more . . . well, hi-fi. In a way, that's true—but not in a pejorative sense. The Schoppered 124 sounded every bit as tuneful, colorful, and substantial as the original, yet it simply had more bass and treble extension, and clarity throughout.

I've tried, as much as possible, to swap the Schopper upgrades one at a time to my own TD 124 Mk.II; as of this writing, I've done so with all but the newly manufactured upgraded bearing and Gino Bertolo's remade motor. Taken in isolation, the only one that failed to impress me was the new upper platter, which did seem a bit "hi-fi" to me. That finding surprised me so much that I came back to it time and again—and, yes, although the Schopper platter sounded better, I preferred the musical presentation of the old one on my player. Apart from that, each Schopper component raised the sound and musicality of my Thorens to a higher level. And the Schopper main platter was especially wonderful, endowing the old 124 with a greater dose of drama during the loud bits, and greater poise and calm during the quiet ones—although before I heard the improvement, I had to remember to compensate for the new platter's nonmagnetic properties by resetting the tonearm's downforce. (The old platter increased the effective tracking force at the level of the record by a significant margin, simply by pulling down on the cartridge's magnet.)

. . . like the tropical fishes

There are a great many ways to skin every hi-fi cat, and a great many followers of every different way. So it goes in the world of turntables—where, I confess, the Linn LP12, with its belt-drive platter and low-power motor, seemed so right for so long that other ways seemed wrong by comparison. What an idiot I was.

I can't help seeing yet a different parallel—this one to the world of the very-low-powered single-ended triode amplifier. To those who've made peace with (high) power, the average SET must seem awfully wrong. And if there were no high-sensitivity, high-efficiency loudspeakers in the world, that impression would be reasonable. Yet there are . . .

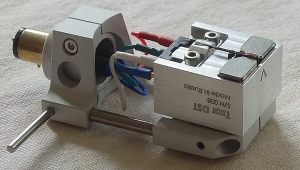

Now I wonder about low-torque motors driving record grooves under high-compliance cartridges (think Shure V-15), and high-torque motors driving records under low-compliance cartridges (think Ortofon SPU). Over the years, I've worried so much about matching turntables to tonearms and tonearms to cartridges that I may have missed an even more crucial point: matching the turntable with the cartridge. Now that the Thorens has captured my heart—no other way of putting it—I'm turning my attention to those things I've missed along the way.

Digital dissident though I am, I've never been comfortable in analog's amen corner, simply because the commonly stated reasons for loving vinyl—smoother highs, greater spatial depth, more timbral warmth, et al—aren't my reasons. My reasons have almost nothing to do with sound and everything to do with music: Except for the best DSD applications I've heard, music that's recorded and played back digitally doesn't have the momentum that I hear in even the grungiest, lamest analog settings. Digitized music doesn't flow from note to note the way real music does—and that's something that analog does routinely well, apparently without trying.

That's what I hear when I listen to my Thorens TD 124 Mk.II—only more so: Not just sounds being pushed at me, but lines of notes being pulled along in front of me. Lately, that has made all the difference.

- Log in or register to post comments