| Columns Retired Columns & Blogs |

Graham Robin tonearm Friction and How to See It

Sidebar: Friction and How to See It

Why fret over friction at all? Because it causes distortion, and because it brings wrack and ruin to your records.

Below a certain level, residual friction in a tonearm's bearing—whatever the type—doesn't interfere with record play, and I doubt whether a change of, say, a tenth of a gram in either plane of motion would make an audible difference, all other things being equal. But as friction approaches a significant percentage of the tracking force, its effect becomes critical.

In the vertical plane, even very high friction wouldn't matter if records and record mats were perfectly flat, if turntable platters and bearings were perfectly true, and if all those parts weren't susceptible to vibrational movement relative to the tonearm. Unfortunately, perfection doesn't exist in this world, and even goodness is elusive.

In the vertical plane, even very high friction wouldn't matter if records and record mats were perfectly flat, if turntable platters and bearings were perfectly true, and if all those parts weren't susceptible to vibrational movement relative to the tonearm. Unfortunately, perfection doesn't exist in this world, and even goodness is elusive.

In order to stimulate the moving parts of the phono cartridge, the modulated groove requires a combined cartridge and tonearm mass that will stay still, assuming that those modulations zip past at a certain minimum velocity. But a vinyl warp occurring at only one place along a record's circumference represents a much lower velocity—it comes along only 33.3 times every minute, on average—and so this imperfection must be able to move the cartridge and arm with perfect ease. Bearing friction severe enough to impede this movement will cause mistracking at that portion of the groove, resulting in dynamic compression, gross distortion, and severe groove damage.

In the horizontal plane, the stakes are arguably more obvious but no less severe: If bearing friction approaches or exceeds half of the downforce, the compliantly anchored cartridge cantilever has a hard time pulling the comparatively massive cartridge body and tonearm along as the stylus follows the groove spiral, resulting in uneven loading of the groove walls—and more gross distortion and record wear, not to mention channel imbalance.

Surely there exists some formula into which we could plug the physical size of the groove modulations, the range of velocities at which they move the stylus and the combined mass of the cartridge body and tonearm, and predict precisely how much tonearm bearing friction, in grams, can be allowed before gumming up the works. I'm not clever enough to come up with one myself. (Newton's Second Law of Motion comes close in a general way, but I'm still leery of mentioning his name in the context of turntables and tonearms after the whole you-know-what affair of the mid-1980s.) Absent such a thing, I'm content to approach the subject more empirically, and after several years of fussing around with tonearms and cartridges, I've drawn certain parallels between the distortion I hear (or don't) and the friction that I see.

But how can you see friction?

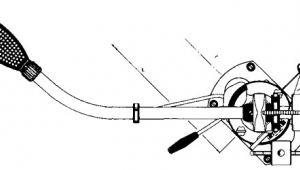

Easy. With your tonearm and cartridge mounted and otherwise ready to roll, and with the cueing lever in the play position, adjust the counterweight and/or downforce mechanism to balance the arm. You want it to float freely, with the armtube parallel to the surface of the platter and poised a few millimeters above the cueing platform.

(Special note to owners of the Rega RB-300 and its descendants: Your tonearm has a magnetic antiskating system, and even when it's set to "0," the magnet remains close enough to exert some residual outward pull. To get the Rega to float freely in both planes, you'll need to unbalance the plinth by shimming the 'table's right-front foot. Take all the obvious precautions before doing this: Clip the arm in the arm rest, put the stylus guard in place, and remove the platter altogether for extra insurance.)

Now look closely at the gap between the tonearm tube and the cueing platform, and use your finger to gently nudge the former down to where it meets the latter—then immediately take your finger out of the way and let the arm come back up. Ideally, it will return quickly to where it was, and you'll see the same gap as before. If it moves slowly, and assuming there's no damping (I forgot to mention that), then the arm is trying to overcome residual friction in the bearings. If it comes only partway back, there's still more friction. If the tube stays where you left it, there's a lot of friction—certainly enough to make its presence known in terms of record wear and at least mildly lousy sound.

If what you have in mind is comparing the bearings of two arms of similar mass, you can put an even finer point on it: Cut out a strip of construction paper 3" long by ¼" wide. (Audiophile hint: Red paper will make the sound warmer, if that's what you want.) Hold one end between your thumb and forefinger, and use the other—gently!—to try to lift the entire arm straight up, using the stylus tip as your lifting point. The trick is to observe carefully how far the strip of paper deflects before the arm begins to move.

I've "calibrated" my paper strip using my Technics SH-50P1 electronic stylus-pressure gauge, and I've found that a mild deflection—say, less than 15 degrees—signifies friction of less than 0.1gm with arms of reasonable mass, while a 90 degrees deflection or greater means a good (actually, a bad) half a gram of friction. No offense to Syrinx PU2 owners, but a mere paper strip will be useless for this test. Try a tongue depressor.

Here comes the trickier part: Use the far end of your paper strip to move the arm laterally—again, with the stylus as the point of contact. The armtube will have no particular reason to return to the position from which you've thus coaxed it, but you'll at least be able to see how easily it moves, and the paper deflection will, again, give you some relative idea. (I know this technique is bogus as an absolute measurement of friction; as it says on your horoscope, this is for entertainment purposes only.)

Other caveats: Theoretically, this approach is probably better suited to a unidirectional bearing of more or less predictable load—like a bicycle wheel. At least in its vertical plane, a tonearm is required to move back and forth unpredictably, in a continuous scrubbing motion. That, of course, is also one of the reasons it must be preloaded and adjusted competently. Keep in mind, too, that your arm may be statically or dynamically balanced to work at its best throughout only a narrow range of vertical movement—appropriately, of course—and if a zeroed-out arm seems difficult to move beyond a certain point, it may not be bearing friction at all that you're observing.

The point of all this being that the Graham Robin ranks with the best I've seen in terms of the quality of its bearings: You can't do much better, friends and neighbors.

Other high and low points?

• I wasn't kidding about the Syrinx: I've owned two myself and observed two others close up, and their bearings were utter crap, notwithstanding some other very appealing aspects of their design.

• Zetas (remember those?) were variable: Some were great, some were horrid.

• Even the cheapest Rega arms—not counting their pre-1983 Lustre-sourced arms—have insanely good bearings for the money.

• Next to the Graham, the lowest friction I've seen in the vertical plane was in an SME V; the lowest I've seen in the lateral plane is in my own Naim Aro.—Art Dudley

- Log in or register to post comments