| Columns Retired Columns & Blogs |

Hi there,

Thanks for this very interesting explanation.

There are 2 things though:

It is stated that it would be good to have a alignment tool delivered with cartridges that obviously is referring to the cartridge body:

I have found that cantilevers and styluses are never 100% aligned correctly, so how to deal with this?

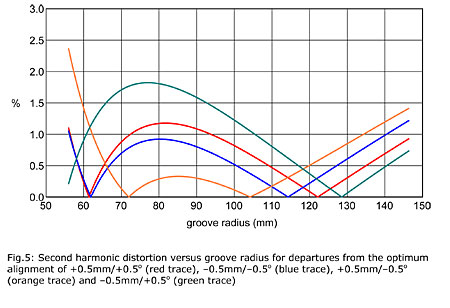

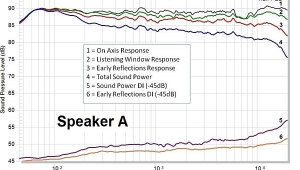

The other thing is the Lofgren B method on which you comment that the approach does not make sense to you because of, as I read it, the higher distortion at the end of the disc.

If I look at my records, most of them don't have modulated grooves there where Lofgren B is exceeding the distortion of the max mid area distortion of the Bearwald, so therefore I think that Lofgren B is the better one...(for me at least)