| Columns Retired Columns & Blogs |

High-End Standards

The American computer industry was a little shaken up to learn recently that the Japanese micro manufacturers had gotten together and standardized their component interconnections so that any Japanese computer will (supposedly) plug into any Japanese printer, modem, or competing computer, and work right off the bat. Anybody who has tried to fire up an Apple computer with a Diablo (Xerox) printer will appreciate what the Japanese move means in terms of compatibility. It means "For no-hassle interconnections, buy Japanese."

Footnote 1: Probably because they make only a small percentage of truly high-end equipment.—Larry Archibald

This isn't the first time others have fait accompli'd a standard into our laps. In the audio field, the most memorable example was "home digital," where the Japanese set the standards and simply told us what formats our amateur PCM adaptors and Compact Discs would use. Since they were the sole source of these goodies, we had no choice but to accept.

The Japanese have not done as well in other areas of high-end audio compatibility. But then, neither have the Americans. We still encounter preamps that won't drive power amps (or have so much gain they are noisy), speaker cables that won't fit speakers without adapters or extensive fudging, and turntable bases I that aren't deep enough to accommodate half of the tonearms on the market. We don't know why the meticulous Japanese haven't brought order to this high-end chaos (footnote 1), but since they haven't, here's America's opportunity to do what is becoming increasingly necessary—before it's done unto us.

Here's a small sample of what needs to be done:

Loudspeaker Input and Amplifier Output Connections

Nobody much cares what cable connectors are supplied with a loudspeaker that comes with 20 feet of #24 zip cord. The manufacturer of such a device is clearly oblivious of or indifferent to such niceties as low inductance, low DC resistance, and high fidelity. ("Duh, what's damping factor? I bet it's a place where they make humid-ifiers, yuk yuk.") But $2000/pair speaker systems, or even some cheaper ones I can think of, were probably designed to sound a certain way by someone who listened to them before finalizing that design, and you can bet your lower-most buck he didn't use #24-gauge zip cord to connect his Stasis S/150 amplifier to them.

Perfectionist speaker (and amplifier) manufacturers are aware that speaker cables, and interconnects, are almost as important as the speakers and their crossover networks. Yet, if we are to judge by the haphazardness of the interfacing connectors they supply, their concern for maximal performance would seem to begin or end at the interconnects.

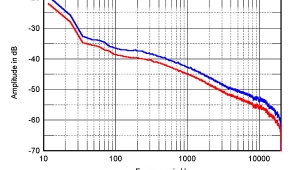

Most of the connecting devices available for speaker cable are wholly inadequate. When he was promoting his brute-force loudspeaker connectors (gold-plated and about the diameter of your average mouse), FMI's Mahatma Fulton used to pass out spectrum analyzer oscilloscope photos showing the voltages developed between a loudspeaker cable and the speaker itself when banana plugs were inserted in the circuit. These voltages represented signal losses, and the implication of those photos was enough to send a perfectionist running for his pacifier.

So, for our first high-end standard, let's adopt two varieties of amplifier-output and loudspeaker-input connectors: one for high current capability and the other for lower current applications.

Fig.1: The barriers (separating ridges) on a heavy-duty barrier strip are spaced 13/16" apart.

For an amplifier that can deliver unusually high current (say over 10 amps) into a 1 ohm load, and for any loudspeaker which can benefit from use with such an amplifier, the only kind of connector which makes sense is a barrier strip with 5/16" screws (fig.1). Although less convenient to connect and disconnect than banana plugs, barrier strips provide the next best thing to a soldered connection when it comes to making positive electrical contact. The smaller-sized barrier strip should be abolished completely, for a reason I'll get to subsequently. Something even more welcome would be barrier strips with brass thumbscrews or wingnuts to provide lots of pressure without tools. We won't insist on those since we've never seen them available, but I think someone could make money manufacturing them.

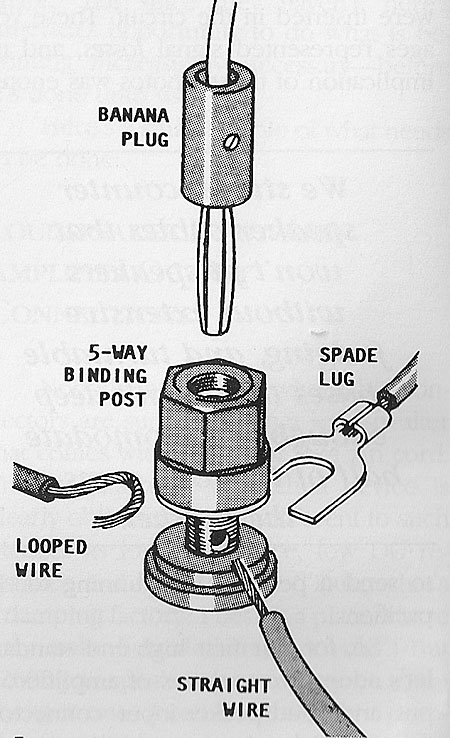

Fig.2: Four ways to connect to a 5-way binding post. (We haven't figured out what the fifth way might be.)

For lower current applications, where very small amounts of in-circuit DC resistance have less effect, amplifier outputs and loudspeaker inputs should use the so-called 5-way binding post (fig.2, footnote 2). Whenever 5-way posts are used, they must be spaced ¾" apart so as to accommodate a dual banana plug for those who choose to use banana plugs. And when 5-way posts are used in the bottom of a speaker, they should have enough room around them to allow easy access for lugs or banana plugs, and should leave an easy path for even stiff speaker cable to exit.

For multiple-impedance amplifier outputs (as in most tube amplifiers), the "hot" 5-way posts can be grouped in a ¾"-radius around the ground post so connections may be chosen merely by rotating a dual banana plug and inserting it into any desired pair. The outer plugs should be spaced on 60° arcs to provide adequate clearance between them. We notice these things, since we're always connecting and disconnecting amplifiers; Precision Fidelity got a well-deserved pat on the back for designing their M-7A amplifier this way.

Cable Connectors

Fig.3: Easy output selection.

Speaker cables, regardless of current capability or wire size, should be terminated with large (for #6 stud) spade lugs at both ends. Spade lugs will mate with large barrier strips, they can be used in a pinch with simple screw-terminal connectors (which we shall hereafter refuse to recognize as a valid approach), or they can be easily attached to a dual banana plug for quick connect/disconnect use (fig.3). They are also the reason why small barrier strips on amplifiers are to be avoided, because large lugs won't fit small barrier strips.

Footnote 1: Probably because they make only a small percentage of truly high-end equipment.—Larry Archibald

Footnote 2: It's called 5-way because there are supposedly 5 different ways of connecting to it, but I can only think of 4. These are; spade lug around the post, wire around the post, wire through the hole in the post, and banana plug into the post. Can anyone tell me what the fifth is?—J. Gordon Holt

- Log in or register to post comments