| Columns Retired Columns & Blogs |

Listening #27

Our December 2004 issue honored 56 contemporary audio products that stood out from the pack during the course of the year. Of those 56, fully nine were phonograph components (footnote 1), including one—the Linn Sondek LP12 turntable—that's been on the market for something like a hundred years.

Footnote 1: Another seven contained vacuum tubes. Ha!

That news would come as a shock to the casual audiophile of only 20 years ago: Imagine going back in time and telling him that the LP will remain viable for decades to come. You might as well tell the car enthusiast of 1984 that Motor Trend will name the Morgan 4/4 Car of the Year for 2004, and will bestow a special Accessory of the Year award upon the Shell No-Pest Strip.

But LP records endure, thanks to refinements in the way they're made, played—and maintained.

I'll leave it to someone else to describe the merits of different record-cleaning fluids, said someone being our own Mikey Fremer, who will do that very thing before long. These days I'm more interested than ever in the different techniques—and the different machines—that the clever come up with for getting me ever closer to the pure music in the grooves of my LPs.

A good case in point—and please forgive me for repeating yet another story I told in the now-dead Listener magazine—was the time I found on eBay a surprisingly affordable UK mono LP of the Beatles' Sgt. Pepper's Lonely Hearts Club Band. When it arrived, I was disappointed that the record sounded far, far worse than its grading had led me to expect. But after a single treatment with a new record-cleaning machine, the record sounded far better than I'd expected. Thus did I gain the satisfaction that comes not only from having an audibly clean, clear copy of a great recording, but also from knowing that I'd succeeded in screwing a record dealer who was out to screw me.

The year was 2000, and the machine was a Loricraft PRC-3, produced by English turntable maven Terry O'Sullivan from an idea by the late Percy Wilson, former technical editor of Gramophone magazine. The PRC-3 wasn't the first record cleaner from Loricraft, but it was the first machine of its type to break the $2000 price barrier. (I pause to offer a moment of respectful silence to those of you who have begun to fret: a $2000 record cleaner—and this fellow's happy about it?)

Percy Wilson may or may not have been the first to dream up a turntablish product that could wet-wash an LP and then safely dry it in less than two minutes, but the history of domestic audio, such as it is, acknowledges him as the first person to build that sort of thing: On some long-forgotten date in the 1960s, Wilson brought his record-cleaning machine to a hi-fi show in Buxton, England, where it impressed all and sundry.

Among the sundry were our friend, the above-mentioned Terry O'Sullivan, and a gentleman from Surrey named Keith Monks, who would go on to design and manufacture a number of distinctive audio products, including an especially clever tonearm. (I love tonearms, in case you didn't know.) As far as I can tell, Keith Monks Audio, Ltd., was first to offer a commercial record-cleaning machine based on Wilson's ideas, and the KMAL machine was in fact the first such product I ever saw—at a shop in Mount Kisco, New York, called the Sound Mill. Like so many other enterprising hi-fi and record stores, the Sound Mill encouraged customers to bring in their dirty LPs and have them laundered for a price, which I recall was in the neighborhood of 50 cents a pop.

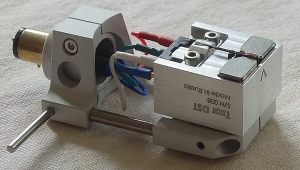

The KMAL machine did resemble a big record player, although its phalanx of clear plastic tubes gave it a more purposeful and altogether damper appearance. Here's how it worked: The dirty record was placed on a rubber-matted platter—no surprises so far—and spun at a fairly high speed. Then a built-in record brush with nylon bristles was pivoted away from its resting place and lowered onto the spinning vinyl. The push of a button activated a hidden pump, and soon it was apparent that the brush was wired for wetness: the wash cycle had begun. When enough was deemed enough, the brush was pivoted back out of the way, and what appeared to be a longer-than-average tonearm was lowered to the record—but on the far side of the label, beginning at the lead-out rather than the lead-in groove (footnote 2). Another button was pushed, and the arm began to suck up all of the liquid, drawing it in through a small opening at its far end. The arm progressed slowly across the record—though not as slowly as if it were actually playing the record—leaving in its wake a remarkably dry and apparently clean surface.

There's one other bit worth mentioning: A short length of sewing thread rode between the surface of the record and the mouth of the vacuum device. On closer examination, this turned out to be not a short length of thread but in fact a very long length of thread, fed from a spool at one end, running under the tip of the arm, and going back through another tube toward wherever it was the spent fluid ended its days. It was also apparent that the thread was continuously played out and renewed by some unseen mechanism.

The sales clerk told me that the thread was part of the cleaning system, and that it rode in the groove to help wick away whatever contaminants required wicking: one of those rare explanations that managed to be both colorful and convincing. But if I'd been smarter or more cynical, I might have wondered how a thread could luge its way from the inside of the record to the outside in only a fraction of the time it would take a needle to do it, even at 78rpm. (Scarier still are the audio reviewers—now as then—who persist in that misunderstanding.) In fact, the thread was merely a cushioning spacer, without which there was insufficient air intake for the vacuum to work well. And the thread required constant replenishing only because it couldn't do what it did without getting wet, dirty, and frazzled—not unlike the parent of a small child.

That's how the KMAL machine worked—and continues to work: I'm happy to say that Keith Monks is very much with us, and his record-cleaning machine has so far sold 12,000 units (footnote 3). The Loricraft PRC-3, which I've already suggested is somewhat simpler and a good deal less expensive, does virtually the same thing, except that it requires the user to apply the cleaning brush to the record himself, and to dispense the fluid of choice manually, as well. Nor is its thread dispenser automated, as in the KMAL machine; the user must manually advance it by a quarter inch or so after every record side.

And because the Loricraft PRC-3 is physically smaller than the Monks, one or two other corners are cut. With the KMAL machine, the user is spared the indignity of looking at the spent fluid and thread, because they go to a hidden tank. But with the Loricraft, fluid and thread are sent to a glass jar strapped to the outside of the enclosure. The KMAL's more extensive and expansive cabinet also gives the luxury of a recessed working area, which cuts down on splashing: The Loricraft can be messier if used without caution.

Footnote 1: Another seven contained vacuum tubes. Ha!

Footnote 2: A blanket clarification: I do in fact realize that most records contain only two grooves—one per side—although I refuse to let that inconvenient fact intimidate my prose. Just bear with me.

Footnote 3: Keith Monks' machine is distributed in North America by Digital Audio Restoration of Ontario, Canada.

- Log in or register to post comments