| Columns Retired Columns & Blogs |

Analog Corner #245: SME Model 15 turntable, SME 309 SPD tonearm

In the April 2000 issue of Stereophile, I reviewed SME's Model 10, which was an attempt by that storied company to produce an "affordable" turntable. I described the Model 10's $5500 turntable-only price—about $7600 in today's dollars—as "stiff." (At the time, the Model 10 cost $5995 with SME's M10 arm, or $8250 with their IV.Vi arm.) But 16 years later, the same Model 10 costs only $5000 ($7000 with the more recent Model 10 arm, which is superior to the M10) (footnote 1).

Footnote 1: SME Limited, Mill Road, Steyning, West Sussex BN44 3GY. England, UK. Tel: (44) (0)1903-814321. Fax: (44) (0)1903-814269. Web: www.sme-audio.com. US distributor: Acoustic Sounds Inc. Salina, KS 67402 (2016); Bluebird Music Ltd., 1100 Military Rd., Kenmore, NY 14217. Tel: (416) 638-8207. Web: bluebirdmusic.com (2024).

Today, a turntable price of $7000, while not exactly cheap, can't be called stiff. What happened between then and now was a vinyl revival beyond anyone's imagining—even mine—and a revitalization of the turntable market that has produced far greater competition at every price point.

For manufacturers of luxury turntables—or any high-priced goods—the challenge is to follow up a flagship product with less expensive versions that don't cheapen the brand, but that approach the top model's standards of technology and build quality. The Model 10 maintained the exceptional build quality of SME's higher-priced models—lower build quality seems not to be part of SME's DNA—but it lost some of the technology, including the unique suspension system incorporated into every other SME turntable model. (That suspension design was first seen in the original wooden mockup made by SME's founder, the late Alistair Robertson-Aikman.) And the Model 10's original M10 arm bore little resemblance to SME's higher-priced tonearm models.

Now comes the Model 15 turntable, priced at $7399 without arm, or $9299 with 309 SPD (for Silver Print Detail) tonearm. SME originally intended that the Model 15 would replace the Model 10, but instead has continued to produce both, the 15 now filling the gap between the 10 and the updated Model 20/3 ($11,999 without arm). That means SME now offers turntables at $5499, $7399, $11,999, and $23,199 (the Model 30/2, which actually was more expensive, at $24,999, when I reviewed it for the March 2003 issue).

Model 15 Particulars

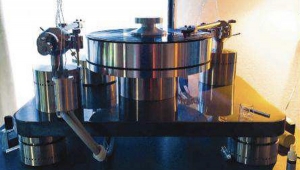

With the Model 10, SME literally cut corners: That compact model was the company's first turntable with a circular chassis. The Model 15, too, has a chassis in the round, but incorporates all of the design and setup features of the more expensive models, including the suspension system omitted from the Model 10.

The Model 15's platter is machined from aluminum alloy and weighs slightly over 10 lbs. Like other SME platters, this one's record-support surface is diamond-turned with a fine scroll pattern, which is said to create thousands of tiny fibers that contact the LP's underside. A screw-on reflex clamping system further ensures intimate contact of platter and vinyl.

In combination with that platter, the 15's machined-aluminum subchassis weighs 24lb, and is suspended from three towers—as opposed to the four used for SME's rectangular turntables—by means of a total of 30 molded O-rings, designed and made for this purpose. The result is a high-mass platform that's well isolated from both ground-borne vibrations and from the motor, which sits on the stationary chassis, below.

A cup of viscous fluid at the center of the chassis damps the platter-speed fluctuations that can happen when the rotation of the platter—even one as well-balanced as this one—creates a rocking "porch glider" motion of the subchassis, relative to the fixed motor pulley. An O-ring stretched between the bottom of the subchassis and the chassis below provides additional stability.

A sealed bearing housing fitted with sintered bronze bushings of reportedly generous size supports the ¾"-diameter main spindle, machined from high-chrome tool steel, which supports the platter.

The 15's three-phase, brushless inductance motor uses neodymium magnets and three integrated Hall-effect position sensors, and is driven by a microprocessor-based controller housed in the turntable's outboard power supply. The platter can spin at 331/3, 45, and 78rpm, each speed adjustable in increments of ±0.1%.

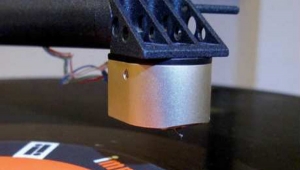

SME Model 309 SPD tonearm

Like the Model 15 turntable, the Model 309 SPD tonearm is a new variant on an old theme. The arm tube is made from a single piece of magnesium and has internal constrained-layer damping. A detachable cast-magnesium headshell has a new type of coupling that, SME claims, permits the rapid swapping in and out of cartridges without compromising overall arm rigidity.

At the arm's pivot, a said-to-be-massive yoke holds a stainless-steel cross shaft that rides on precision ball-bearings in 10mm races; according to SME, this highly rigid assembly allows the bearings to be critically adjusted before the tonearm tube is fitted. Inside the 23mm-diameter steel pillar, a stainless steel bearing shaft rides in two widely spaced 17mm-race ball bearings. The 309 SPD's spring-and-filament antiskating system is set with a calibrated dial that includes a positive Off position.

Once installed, most tonearms exhibit a fixed distance from their pivot to the platter's spindle, and their headshells have adjustment slots to accommodate a range of stylus-to-cartridge-mount dimensions. SME's system takes the opposite approach: The headshell offers the cartridge a single fixed mounting position, while the pivot-to-spindle distance can be adjusted via a tonearm mount that moves forward or backward along a sliding track, after which it's locked tightly in place. Because the cartridge's position relative to the arm pivot is fixed, you can first set the vertical tracking force (VTF), which will remain constant as you adjust overhang. The underslung, locking tonearm counterweight, made of a tungsten alloy, slides on a two-point damped suspension.

The 309 SPD's pivot-to-spindle distance is specified as 215.35mm; add to this a specified overhang of 16.97mm and you have an overall effective length of 232.32mm: As its name implies, the 309 SPD is a 9" tonearm.

Setup: Easy if you know the drill

The SME Model 15 arrives in need of assembly and lubrication. Place it where you want it, choose ball footers of rubber or metal (both are provided), remove the two transit screws, loosen the screws that hold the platter in place, fill the bearing with oil (also provided), unlock each suspension tower, adjust the height of the subchassis using the supplied gauge, and you're almost ready to go.

Now all you need do is unscrew the motor holddown, place the platter over the spindle, attach the motor controller to the turntable, plug it in, and calibrate the speed. This can all be done quickly and precisely, especially so if you've ever installed one of the bigger SME 'tables.

Setting up the 309 SPD tonearm is equally easy, especially if you're familiar with SME's Series IV or Series V arms. Setting overhang, VTF, vertical tracking angle (VTA), stylus rake angle (SRA), and antiskating are particularly easy, though adjusting SRA on the fly isn't possible—or really necessary, in my opinion, if you use a digital microscope and set it at 92°. Connect the supplied DIN-to-RCA cable or use your favorite, and now you're ready to spin vinyl until you can no longer hear—a compulsion shared by my new friend, 99-year-old Norman C. Pickering. Yes, that Pickering! (footnote 2)

The Model 15 is easily SME's most graceful-looking turntable. Making the plinth circular, and having three regularly spaced suspension towers instead of one at each of four corners of a rectangular plinth, produce a far more elegant appearance, and that frontmost tower adds visual drama. And SME's aesthetic of matte black is now so far out of style it's back in. I didn't try it, but I imagine that mounting a Kuzma 4Point arm on the 15 would make one powerful-looking record player—one that analog devotee Vladimir Putin would probably admire (though not to the same degree as Medvedev).

Like other SME turntables, the Model 15 is an heirloom product, designed and built to last many lifetimes. A few years ago, after attending the Munich High End show, I visited SME's factory (above) in Steyning, in West Sussex, and witnessed the Swiss-like way they make things. It was impressive in every way. Other companies apparently agree, which is why SME does a great deal of contract work—although most of the machining they do is for their own products.

As you'd expect of a precision-made product, the Model 15 was an absolute pleasure to use. Both the 'table and the 309 SPD arm had an admirable feel. The platter started and reached speed quickly. The suspension worked as advertised: When I tapped the top of the Harmonic Resolution Systems base on which the SME sat, nothing got through to a stylus sitting in the groove of a stationary LP. When I tapped the SME's own chassis, same result.

Footnote 1: SME Limited, Mill Road, Steyning, West Sussex BN44 3GY. England, UK. Tel: (44) (0)1903-814321. Fax: (44) (0)1903-814269. Web: www.sme-audio.com. US distributor: Acoustic Sounds Inc. Salina, KS 67402 (2016); Bluebird Music Ltd., 1100 Military Rd., Kenmore, NY 14217. Tel: (416) 638-8207. Web: bluebirdmusic.com (2024).

Footnote 2: You can meet Norman C. Pickering (please do!) here.

- Log in or register to post comments